There are many difficulties in the disposal of lithium-ion battery waste. For example, discharging too quickly may cause the battery’s internal temperature to rise too fast. This affects battery life and safety. Therefore, specialized discharge equipment is necessary for efficiently handling large lithium battery packs or battery packs. However, discharged lithium batteries have important safety, environmental protection, and battery life problems. Therefore, by correctly handling the discharge of lithium batteries, you can better protect the environment and extend the battery’s service life. More importantly, for lithium-ion battery waste how to discharge, our company has its own set of equipment and treatment programs.

Two ways of discharging lithium batteries.

The raw materials processed by this process are all kinds of monomer lithium batteries. Such as soft pack batteries, cylindrical batteries, and so on. And you need to discharge according to its different characteristics.

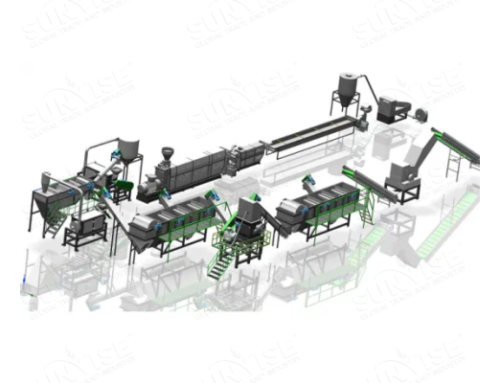

After discharging different batteries, operators drop them into the discharge cooling box for water cooling.In order to prevent problems such as smoke generated during the discharge process. So after discharging different batteries, you need drop them into the discharge cooling box for water cooling. In addition, you need process discharged batteries through crushing and sorting equipment for recycling purposes.Processing discharged batteries for recycling purposes involves crushing and sorting equipment.

What equipment is involved in discharging lithium batteries?

Regarding the problem of how to discharge lithium-ion battery waste, our company can provide the following two devices to solve this problem.

Acupuncture discharge equipment

The equipment feeds charged lithium-ion batteries through a conveyor, and then acupuncture rollers discharge the lithium-ion batteries. By adjusting the gap between the needle roller and the feeding table, you can meet the discharge needs of different types oflithium-ion batteries.

Spray equipment

Send the needle-discharged lithium-ion battery into the mesh belt conveyor. A spray device cools the temperature during the transportation process. And then a water tank is equipped at the lower part of the conveying device.

What is the price of our lithium battery discharge equipment?

The price of lithium battery discharge equipment is affected by many factors, such as processing capacity, model, material, and other factors. If you want to discharge lithium batteries on a small scale, then I recommend the YS-150 needle discharge equipment. Because it is not only cost-effective at only about $1,000 but also has excellent processing capacity. In addition, if you need to consider the price of the equipment, then I recommend you choose the YS-200 needle discharge equipment because it is not only widely applicable but also only costs about $800. In short, if you are interested in lithium battery discharge equipment or electronic waste recycling equipment, welcome to consult us.

Why choose us as a lithium battery discharge equipment manufacturer?

Because we have many years of professional equipment design capabilities and rich practical experience in electronic waste recycling as a lithium battery discharge equipment manufacturer. The following are some of our advantages in various aspects.

Leave A Comment