PCB recycling is a complex and important process. Hence the need for specialized technology and equipment. However, because the printed circuit board not only contains a large number of metal resources, but also contains a large number of harmful substances. Therefore, the recycling of printed circuit boards has important significance and value for resource reuse and environmental protection. Because of the current environmental policy, there are many technologies and equipment for recycling printed circuit boards. However, our company’s printed circuit board recycling solutions and equipment are definitely worth your choice.

What materials in printed circuit boards can be recycled?

Printed circuit boards contain many valuable materials that you can recycle them, including the following.

Plastic

Because the plastic material of the printed circuit board mainly uses polyester resin, epoxy resin and other polluting substances. So recycling and reusing them can reduce environmental pollution.

Glass fiber

In addition, the substrate material of the printed circuit board usually uses glass fiber reinforced resin. Therefore, the recycling of glass fiber can reduce the waste of resources.

What is often overlooked are the following two materials.

Organic compounds

More importantly, the proper handling and recycling of solvents and additives in the printed circuit board. This will not only reduce the need for fossil fuels but also reduce pollution to the environment.

Metals

Finally, printed circuit boards contain many metals. Such as iron, copper, lead, mercury, cadmium and so on. However, some of these metals are toxic. Therefore, recycling them can not only avoid environmental pollution but also make resources recyclable.

How to recycle printed circuit boards?

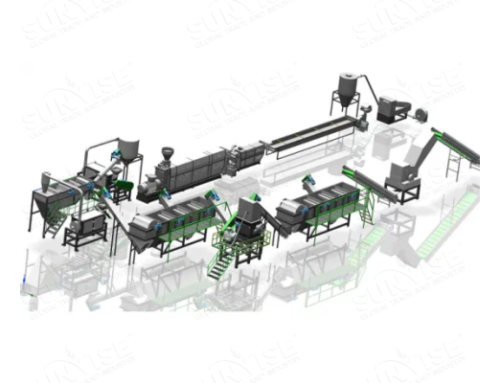

Our company provides the following methods of recycling printed circuit boards through our printed circuit board recycling equipment.

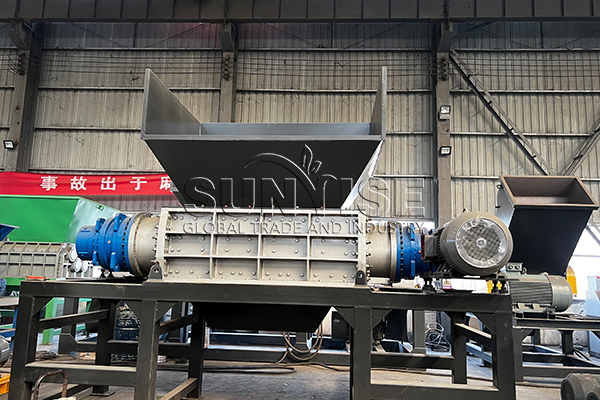

First of all, shred the bare board to 2-3 cm.

Secondly, crush the crushed circuit boards to about 20 mesh.

Third, it can screen the crushed material to separate resins, copper, dust and fibers. At the same time, the induced draft fan draws the dust and fiber into the collector, and the resin and copper into the grading screen.

Collects dust and fibers, and discharges the collected fibers.

Fourth, collect the dust and microfibers produced during the crushing process.

Next, screen resin and copper. It can return the unseparated resin and copper to the main machine for crushing.

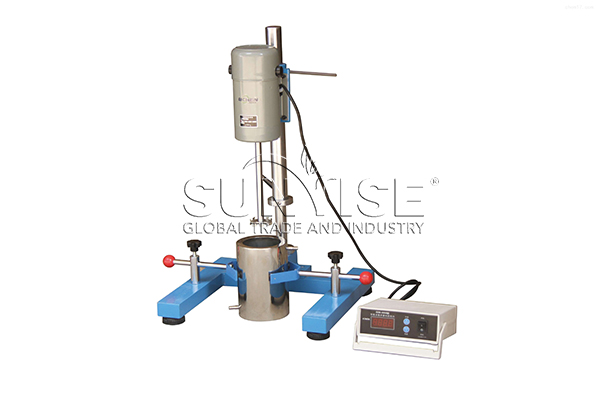

In addition, the specific gravity separates the resin powder from the copper. Since copper is heavier than resin, it is possible to separate them. It is certain that this is the most advanced technology in the country, which can achieve more than 99% of the metal sorting effect.

Finally, the tailings of the specific gravity separator are separated by high voltage electrostatic separation. Thus, fine copper powder and resin can be separated.

Leave A Comment