With the popularity of electronic products and the increase in the speed of replacement, electronic waste has become a serious environmental problem. However, electronic waste contains a large amount of precious metals, such as gold, silver, copper, etc. The recovery of these precious metals is of great significance for resource recycling. Methods for recovering precious metals from electronics include pre-processing, rough sorting, fine sorting, and rare metal extraction. We can effectively separate precious metals in electronic waste by conducting sorting processing. Further processing and refining results in high-purity precious metals. We can use these precious metals for recycling, reducing resource waste and also helping to reduce the exploitation of natural resources. The recycling process of precious metals should pay attention to environmental protection and safety issues.Because in order to ensure safe and efficient sorting, avoid environmental pollution.

How to recycle precious metals from electronic products?

Electronic products contain many useful metals, such as copper, aluminum, zinc, nickel, iron, etc.Recycling these metals allows for their reuse, reducing resource waste and environmental pollution. Methods for recovering precious metals from electronics are summarized below.

Sorting

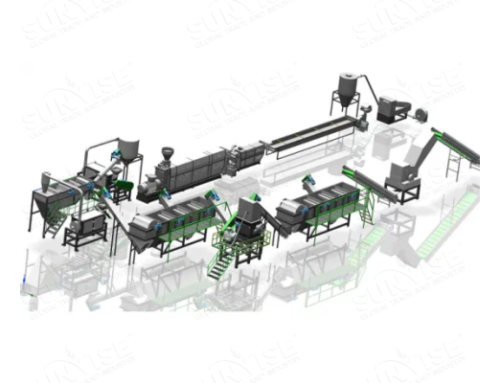

First, you need to sort the waste electronic products to separate different types of metals. Operators use a combination of mechanical devices to separate parts with different metal compositions. Because this ensures efficient separation and proper recovery of precious metals.

Crushing

Crushing the sorted electronic products into small particles. This aids in the subsequent metal separation process.

Magnetic separation

You can use magnetic separation equipment to separate ferromagnetic metals such as iron and steel from other non-ferromagnetic metals. This is a simple and effective separation method.

Air Classification

Air flow is used to separate non-ferrous metals such as light aluminum and copper from heavy metals such as lead and iron. Because the air flow will disperse the light metals, and the air flow will carry the heavy metals to the different collection devices.

What is involved in the cost of recovering precious metals from electronics?

Recycling precious metals from electronics involves the following costs.

Equipment and technology costs

Recycling precious metals requires the investment of advanced equipment and technology. Such as sorting equipment, extraction equipment, etc. There are costs associated with purchasing, maintaining and updating these equipment and technologies.

Transportation costs

Transporting recycled e-waste from collection points to recycling centers also involves costs. Such as transport vehicles, fuel and driver salaries.

Processing costs

After recycling precious metals in electronic products, processing such as refining, purification, etc., requires costs.

Environmental and safety costs

To ensure that the recycling process does not cause environmental pollution. First of all, to ensure the safety of employees, we need to invest in appropriate security measures. That’s part of the cost.

Management and administrative costs

One also needs to take into account the management, supervision, and reporting required for recovering precious metals.

Labor costs

Recycling precious metals requires professionals to operate and manage, and you needs to train them. You need to pay ongoing labor costs for wages and benefits.

Leave A Comment