Solar panels are mainly composed of silicon, silver, aluminum, copper and other elements, through recycling can re-use these valuable resources, reduce the mining of new resources. In addition, recycling valuable elements in solar panels can also bring certain economic benefits. At the same time, recycling supports sustainable development and helps to promote the solar industry towards a more environmentally friendly and sustainable direction. Therefore, the establishment of solar panel recycling plants is very important.

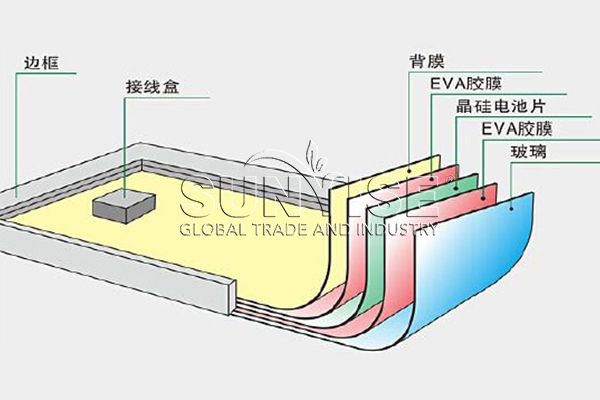

What are the main components of solar panels? What happens to these ingredients during the recycling process?

A solar panel is a device that uses solar energy to convert light into electricity and consists of multiple components. Its main components include silicon wafers, glass, adhesives, metal frames, and wires.

How to buy the right solar panel recycling equipment?

Recovery demand

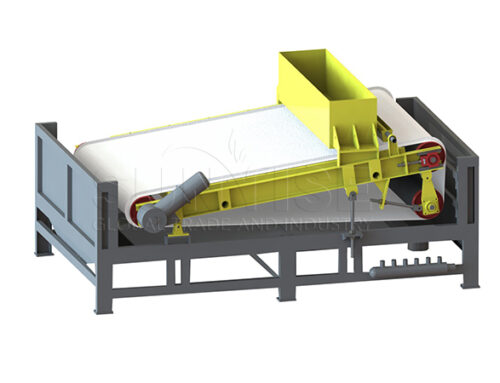

First, you should make sure that you understand and are clear about your recycling needs. Different solar panel recycling equipment is suitable for different scale and process needs. For example, the model YS-500 solar panel frame removal machine has a production efficiency of 2,000 kilograms per hour. However, the YS-800 equipment has a production efficiency of 3,000 kilograms per hour. In addition, the model YS-700 shredder can handle various e-waste recycling equipment, while the model YS-300 shredder can only handle e-waste weighing less than 200kg.

Product Quality

Secondly, product quality is a key factor. There are many suppliers of solar panel recycling equipment in the market, but the quality is uneven.To ensure the purchase of high-quality equipment, you can find the manufacturer’s qualifications and reputation. You can also learn about its production process, equipment performance, and other information. In addition, you can learn more about the reliability and performance of your device by referring to reviews and feedback from other users. If I have the honor to get your understanding, I believe you will choose us as a partner. Because our equipment has professional qualifications and certificates.

Price factor

Finally, price is also one of the important factors to consider when buying solar panel recycling equipment. There are price differences between different brands and different models of equipment, you need to budget within a reasonable range and make a reasonable assessment of the price. For example, our YS-1000 color sorter costs between $7,000 and $9,000, but the model YS-500 color sorter costs only about $4,000. Similarly, the price difference between the YS-800 and YS-500 cracking furnaces is $1,500. In addition, equipment from well-known brands is always more expensive than smaller brands. Which one to choose depends on your needs and budget.

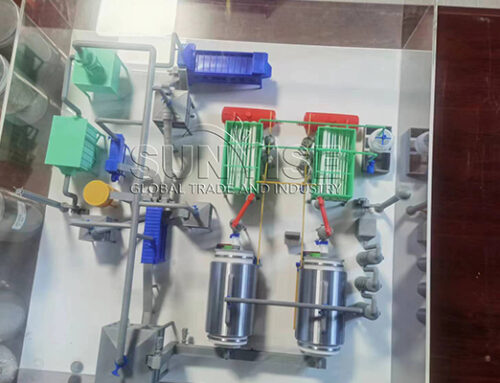

5 Characteristics of our company cracking furnace

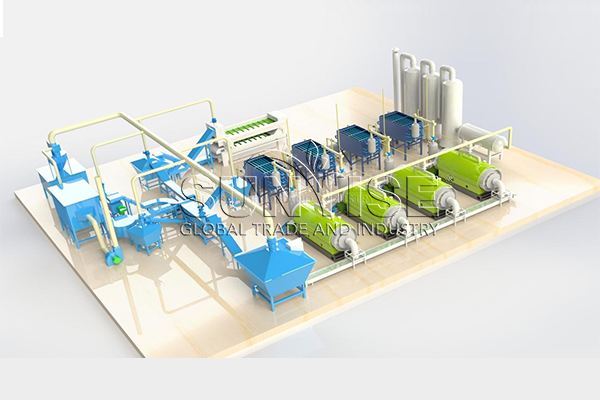

How much does it cost to set up a solar panel recycling plant?

Equipment price

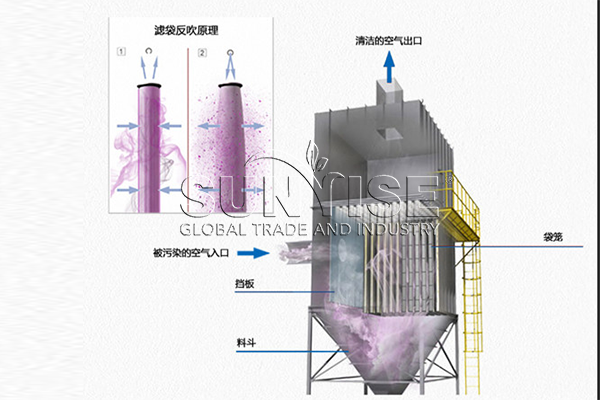

Establishing a production plant with a 5,000 kg per hour output capacity will require specific equipment. Firstly, the $4,000 YS-800 frame remover is critical for operation. The YS-500 cracking furnace, essential for dissolving EVA, is available for approximately $5,000. The YS-500 circular vibrating screen, costing around $4,000, separates silicon. For silicon wafer storage, the $3,000 YS-500 model silo is suggested. Sorting copper requires a YS-700 color sorter, costing $7,000. An air separator is indispensable for your setup; we recommend the $4,000 YS-800 air separator. Lastly, a dust removal unit is pivotal. The YS-400 bag dust remover, priced at around $2,000, should suffice. The total expenditure for all these equipment is about $30,000.

Other costs

Solar panel recycling plants require skilled staff to operate and manage them. This includes engineers, technicians, workers, and managers, among others. The costs will relate to staff salaries, training, and benefits. It’s about $30,000. There is also a space rental fee of about $10,000. All told it costs about $70,000 to set up a small solar panel recycling plant.

Leave A Comment