Lithium batteries are an efficient and lightweight energy storage device, but the harmful metals and chemicals they contain can pollute the environment. Therefore, by recycling waste lithium batteries, can not only reduce the harm of harmful substances to the environment and the human body but also save energy and reduce waste disposal costs. More importantly, precious metals can be obtained by recycling waste lithium batteries. On April 28, 2024, a customer from South Africa wanted to know about the lithium battery recycling production line, and finally, we happily entered into a cooperation.

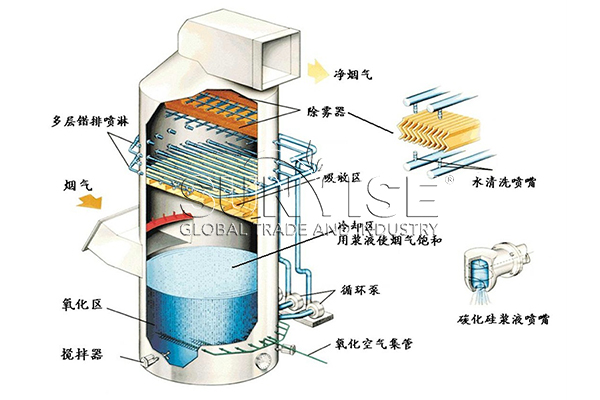

What kind of dust removal equipment is suitable for customers from South Africa?

According to different working environments and dust removal needs, different types of equipment such as spray towers, pulse dust collectors, and activated carbon adsorption equipment can be selected. The spray tower is suitable for treating waste gas, while the pulse dust collector is suitable for applications where the efficient removal of coarse particles is required. Therefore, according to the needs of customers from South Africa, we offer the following models of dust removal equipment.

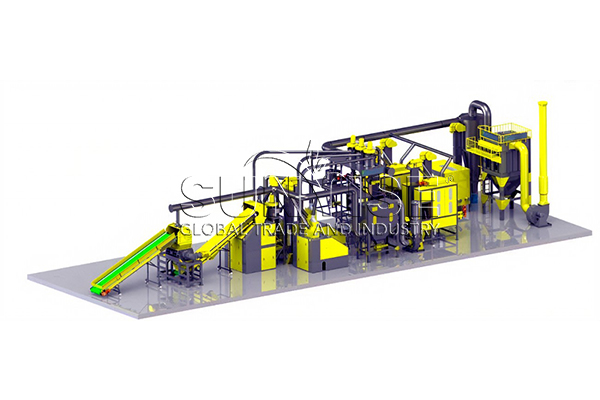

Pulse dust collector

Because our customers from South Africa require efficient dust removal and energy saving and environmental protection, we provide them with the model YS-300 pulse dust collector, which has strong processing capacity and can meet the different scale and requirements of dust removal tasks. In addition, it is also very cost-effective, only about $3,000.

Water spray tower

The customer also needed equipment that could deal with waste gas to further reduce environmental pollution, and they wanted to keep the price under control. So we prepared a water spray tower for them, Model YS-500, which costs only $2,000. Its combination with the pulse dust collector can dust well, reduce environmental pollution, and inexpensive.

How much does 4000kg/h lithium battery recycling production line cost?

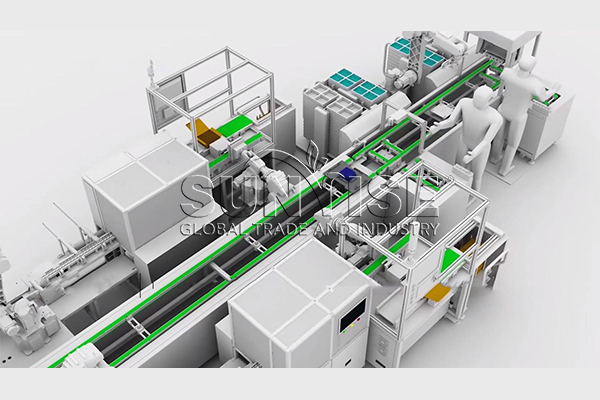

Production equipment

The equipment needed for lithium battery recycling mainly includes shredder, specific gravity separator, hammer crusher and so on. Because the customer made it clear that they needed 4000kg/h production equipment. This is a small-scale production, so we recommend the YS-500 shredder for him, as well as the YS-300 shredder used in the secondary crushing, the total cost of about $18,000.

Labor cost

High-quality human resources are crucial to the operation of the production line. The team of skilled and experienced employees can ensure the efficient and stable operation of the production line, improve production efficiency and product quality. However, the recruitment and retention of such employees requires appropriate pay and training opportunities. Higher salaries are often required, and ongoing training and development programs also require investment of money and time. All told, it’s about $10,000.

Contact Us

Your Content Goes Here

Leave A Comment