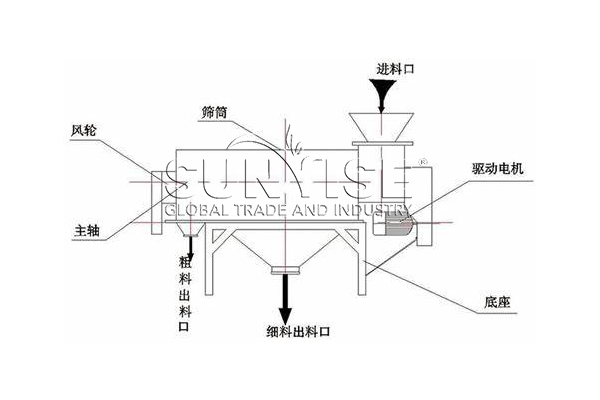

Air flow screening machines play an important role in improving production efficiency and saving energy. It uses the impact force of air flow to carry out precise screening and accurately control the particle size of materials. Effectively control dust emissions during the screening process and reduce environmental pollution. Its structure is simple, easy to maintain, durable and has low investment cost. It has a wide screening range and is suitable for a variety of materials to ensure product quality. Overall, its main functions are to improve efficiency, energy saving, high-precision grading, pollution reduction, low-cost investment and quality assurance.

On May 18, 2024, a customer from Mexico asked us about the price of the screening machine. Because they are doing cell phone battery recycling. Then we briefed them in detail and learned that they wanted equipment with an output of 4,000 kilograms per hour.

What price range of air flow screening machine is suitable for this customer from Mexico?

Our company’s airflow screening machine model YS-500 is very suitable and sells for about US$3,000. This airflow screening machine has the advantages of efficient screening, precise separation, reliability, and stability. Its special airflow separation technology and high-speed motor can achieve high-efficiency multi-stage screening to meet high-yield needs. At the same time, you can achieve precise separation of materials with different particle sizes by adjusting the air inlet speed and screen aperture. What’s more, our equipment is made of high-quality materials, adopts advanced manufacturing processes, and is equipped with intelligent control systems to ensure the reliability and stability of the equipment.

Leave A Comment