Nowadays, lithium-ion batteries are used more and more widely, from mobile phones to electric cars. However, lithium-ion batteries contain chemicals that are harmful to the environment and health, such as lithium, cobalt, and nickel. Therefore, the recycling of lithium-ion batteries has become crucial. However, if you want to achieve efficient recycling of lithium-ion batteries, you need to use lithium-ion recycling equipment.

What is your process for recycling lithium-ion batteries?

What technical challenges does lithium-ion battery recycling face?

Although the recycling of lithium-ion batteries has important environmental and economic significance, its recycling technology faces many challenges due to the complex structure of the battery, the mixing of materials and the different types of battery cells.

First, you need to disassemble the battery during the recycling process, which places high demands on the accuracy and safety of the recycling equipment. In addition, you need to use highly automated recycling equipment to achieve effective disassembly and classification. Secondly, heavy metal elements in the battery, such as lithium and cobalt, need to be effectively recycled through special treatment methods to make the recycling efficiency higher.

What innovative progress has our lithium-ion recycling equipment made?

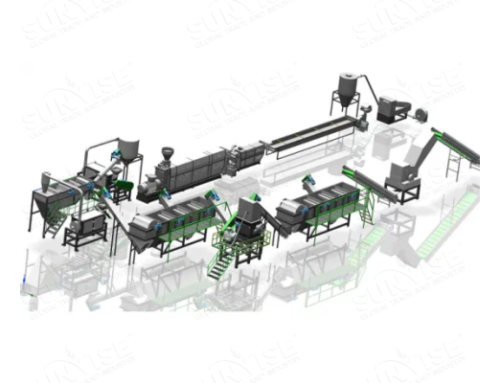

In recent years, with the continuous development and progress of science and technology, our lithium-ion recycling equipment has also made important innovative progress.

First, our new recycling equipment uses advanced technologies such as fine separation and electrochemical recycling, which can better solve the classification and recycling problems of battery materials. Secondly, you can greatly improve the efficiency and recovery rate of recycling equipment through automated control and intelligent management, while reducing labor costs and operational risks.

Leave A Comment