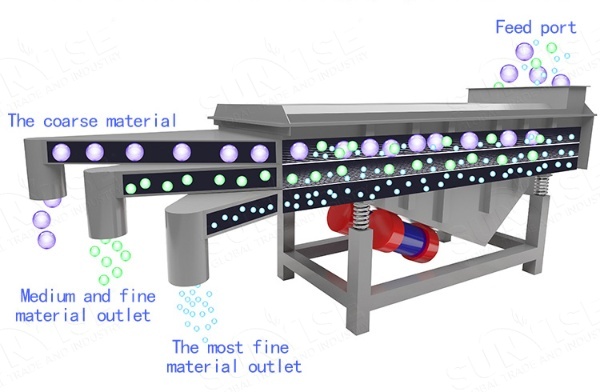

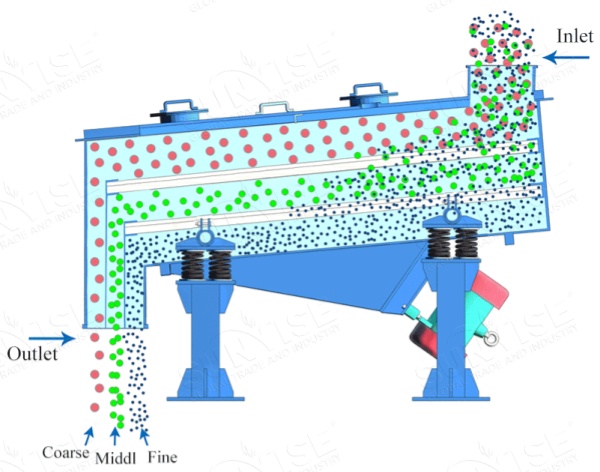

The linear vibrating screen is an efficient screening equipment that mainly uses a vibration motor to generate linear motion to screen and classify materials. In addition, it has a simple structure, easy operation, and high production efficiency. It can be used in single or multiple layers to meet different needs. Our equipment is widely used in mining, building materials, chemical, and other industries. It can significantly improve production efficiency, ensure product quality, save costs, and reduce waste. On June 29, 2024, a customer from Australia sent us an inquiry. They need a linear screen that can process 1000kg of worn-out lithium batteries per hour.

What is the screening efficiency and processing capacity of our linear vibrating screen?

Our linear vibrating screens have several significant advantages in terms of screening efficiency and processing capabilities, which make them very popular among our customers.

Our linear vibrating screens are designed to be compact and efficient, capable of handling large volumes of material in a small equipment size. In addition, our screening equipment has a large screen area and high screening speed, allowing it to process a large amount of materials in a short period of time.

Linear vibrating screens are suitable for screening dry and wet materials and can be adapted to the screening requirements of different materials by adjusting vibration parameters (such as amplitude and frequency). This allows linear vibrating screens to be widely used in many different industrial fields.

Linear vibrating screens have high operating efficiency and consume less energy than other types of vibrating screens (such as circular vibrating screens). When processing the same amount of materials, linear vibrating screens can achieve efficient screening results with lower energy consumption.

How adaptable and reliable are our linear vibrating screen equipment in extreme weather conditions in Australia (such as high temperature and dust)?

The adaptability and reliability of linear vibrating screen equipment in extreme weather conditions in Australia (such as high temperatures and dust) is a matter of great concern to our customers. However, when we design and manufacture this equipment, the following points are key factors to ensure that they can operate under these harsh conditions.

High temperature resistant design:

We use materials with good high-temperature tolerance and a well-designed heat dissipation system to effectively prevent overheating and

ensure continuous operation of the equipment in hot weather.

Dust prevention measures: In dusty environments, dust prevention is an important consideration to ensure the normal operation of equipment. Therefore, we use sealed bearings and motors, as well as appropriate dust covers, etc., which can effectively prevent dust from entering the equipment and reduce wear and failure.

Materials and coatings: In this regard, we choose materials that are suitable for high temperature and dusty environments to construct linear vibrating screens, such as corrosion-resistant and wear-resistant special metals or alloys, and surface anti-corrosion coatings, which can greatly improve the durability and reliability of the equipment.

Leave A Comment