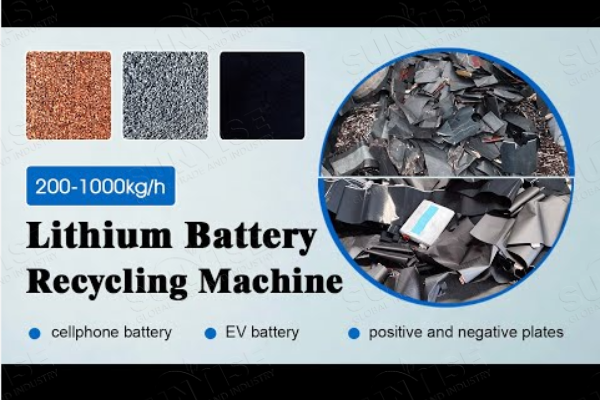

As the global demand for electric vehicles and renewable energy continues to grow, the application of lithium batteries is also expanding rapidly. This makes the development and use of lithium battery recycling equipment particularly important. Lithium battery recycling equipment can not only effectively disassemble and process waste lithium batteries, and recover precious metals such as lithium, cobalt, nickel, etc., but also create economic value. Our company is very professional and experienced in researching lithium battery recycling equipment. On July 6, 2024, a customer from Germany wanted us to provide them with a set of lithium battery recycling equipment to help them recycle used lithium batteries.

What is the precious metal recovery rate of our lithium battery recycling equipment?

Precious metal recovery is one of the important indicators to evaluate the performance of lithium battery recycling equipment, especially for batteries containing precious metals such as cobalt, lithium, nickel and copper. However, the specific recovery rate will vary according to the technical level of the equipment, the treatment process, the type of battery to be recycled, and the pre-treatment state of the battery. However, our professional equipment and technology can guarantee the following data.

First, the recovery rate of cobalt and nickel can reach more than 95%. The recovery efficiency of lithium is relatively low due to the variety of lithium compounds, but our advanced technology can achieve a recovery rate of 90%. In addition, the recovery rate of copper is usually very high, reaching 95 to 98 percent.

What are the main operating costs you need to consider to run our lithium battery recycling equipment in Germany?

There are several operating costs involved in running lithium battery recycling equipment in Germany. Taking into account the high requirements for environmental protection and safety in Germany, here are some of the main operating cost factors.

Leave A Comment