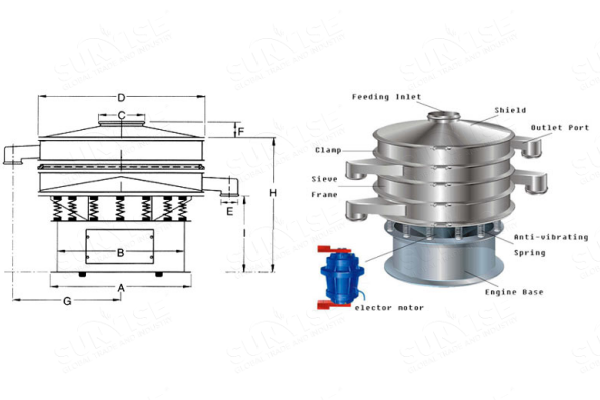

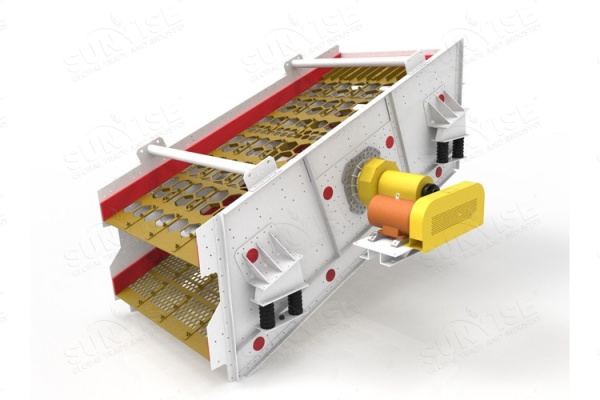

Circular vibrating screen is an efficient and energy-saving screening equipment, widely used in many industries such as mining and building materials. In addition, the electronic waste recycling equipment realizes high-precision grading and screening of materials through the vibration force stimulated by the vibration motor. Its design is simple and easy to maintain. It is suitable for both dry and wet screening methods and can meet diverse industrial needs. In short, our circular vibrating screen can not only improve the recovery rate of precious metals in electronic waste but also has a suitable price. On August 1, 2024, a customer from Germany consulted us about the circular vibrating screen and finally reached a satisfactory cooperation with us.

How efficient is your circular vibrating screen in screening different electronic waste particle sizes?

Since our customers need to use circular vibrating screens extensively, they hope to get a circular vibrating screen with relatively stable recycling efficiency. Generally speaking, the recycling efficiency of a circular vibrating screen is determined by many factors, but our equipment is designed by an experienced team, so we recommend the YS-150 circular vibrating screen for them.

First of all, our electronic waste recycling equipment is equipped with multiple screen apertures that can be replaced according to the different electronic waste you recycle to ensure efficient particle size separation. Secondly, our screen is a screen with a high open porosity and is made of stainless steel. In addition, the vibration frequency and amplitude of the equipment can be automatically adjusted to ensure the accuracy of screening. In short, the metal recovery rate of our circular vibrating screen is stable at around 90%, which can well ensure the recycling purity of various materials.

How does a circular vibrating screen perform in screening materials with high humidity or moisture content?

Since the average humidity in Germany is relatively high and there is a lot of rain in the summer, customers need equipment that will not be affected by such conditions. We customized the most suitable equipment for them according to their needs. Here are the problems that may be encountered in high-humidity weather and our solutions.

Leave A Comment

You must be logged in to post a comment.