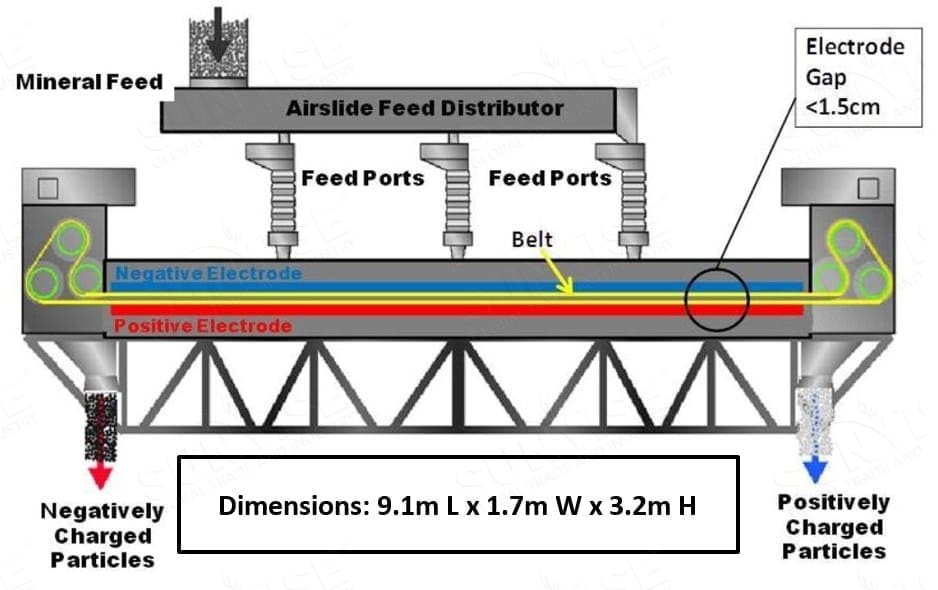

An electrostatic separator is an efficient and environmentally friendly dry separation technology that separates materials by utilizing the difference in the electric force they receive in an electric field. Therefore, it is widely used in mineral processing, waste recycling, and other fields. In addition, our equipment can not only improve resource recovery rate but also reduce processing costs and improve product quality. Our company has specialized in the field of electronic waste recycling equipment for many years and has rich experience and professional technology. On July 28, 2024, customers from Brazil wanted to purchase a batch of electrostatic separators for lithium battery recycling. In the end, we reached a cooperation that satisfied both parties.

5 Design Advantages of Electrostatic Separation Machinery.

Our electrostatic separation machinery has many professional certificates and is electronic waste recycling equipment carefully designed by our design team. Below I will briefly summarize some of the most important advantages for you.

Electrostatic separation is a dry treatment process that does not require the use of water or chemical reagents, thereby reducing water consumption and potential water pollution problems. This feature makes its impact on the environment less than wet separation technology.

Electrostatic separation usually consumes less energy. This is because it does not require heating, drying or a large amount of mechanical stirring of the material.

Because electrostatic separation is carried out under dry conditions, it avoids material dissolution or abrasion losses that may occur during wet treatment, especially for materials that are susceptible to water damage.

For certain material combinations, electrostatic separation can provide higher separation efficiency and product purity, especially when processing fine particles.

Compared with wet separation technology that requires expensive pumping equipment and water treatment systems, our electrostatic separation machinery usually has lower acquisition and operating costs.

What is the price of the electrostatic separator you use?

Our electrostatic separators, like all electronic waste recycling equipment, are priced differently by factors such as manufacturing materials, brand, and processing capacity. However, since our Brazilian customer has given us their specific requirements, such as requiring the equipment to process 700kg of lithium batteries per hour and the price to be suitable, we provide the YS-150 electrostatic separator, which costs about $1,500. Below I will provide you with some price references for electrostatic separators.

Leave A Comment

You must be logged in to post a comment.