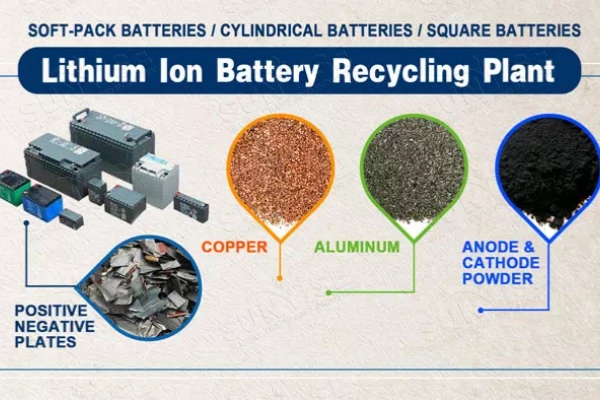

With the popularity of electric vehicles, the number of discarded lithium batteries has gradually increased, and the importance of lithium battery recycling has become increasingly prominent. The key to lithium battery recycling is resource recovery and cost savings. Therefore, you need to increase the recovery rate of precious metals in the recycling process to increase economic benefits. Our company’s lithium battery recycling process has a metal recovery rate of up to 90%, so using our lithium battery recycling equipment can increase the recovery rate.

What is your material recovery rate through our lithium battery recycling process?

Our lithium battery recycling process is leading the industry, not only ensuring a recovery rate of up to 98% for positive and negative electrode powders, but also achieving efficient recovery of 92% of copper, 84% of aluminum, and 99% of black powder. With all of this, we are still able to provide services at the most competitive prices in the industry, ensuring that while protecting the environment, we also create the greatest economic value for our customers.

How can you recycle lithium batteries?

Why can our recycling equipment better help you complete the lithium battery recycling process?

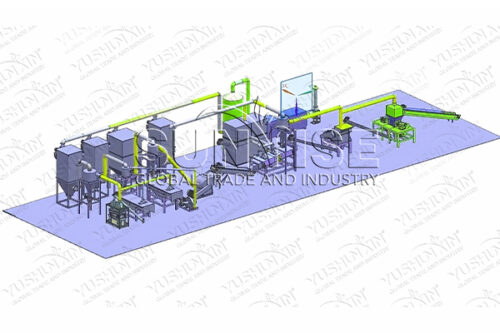

Our e-waste recycling equipment has professional qualifications and unique design ideas, which can professionally increase the recycling rate. Below I will introduce you to some equipment.

This e-waste recycling equipment stands out for its high sorting accuracy, wide range of applications and high operating efficiency, capable of achieving more than 99.9% of effective ingredient sorting. In addition, its adjustment flexibility and automatic circulation system simplify the sorting and collection process, while ensuring long life and easy maintenance. More importantly, this machine operates in a fully sealed negative pressure environment, significantly reducing dust and noise and achieving pollution-free operation. Whether it is objects of different characteristics, types, shapes or sizes, airflow sorting machines can provide accurate and efficient sorting solutions.

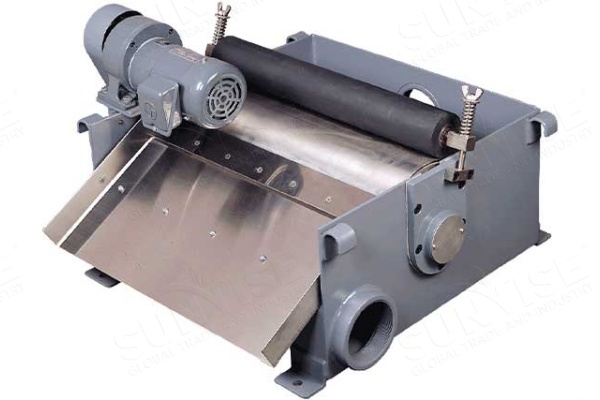

Magnetic separator

Our magnetic separators are divided into two categories. The magnetic system of permanent magnet magnetic separators is mostly made of high-quality ferrite materials or compounded with rare earth magnets. In addition, the magnetic field strength of our roller magnetic separator has been increased to 1650mT, which is the highest magnetic field strength measured so far. At present, it can be specifically divided into: dry strong magnetic field disk magnetic separator, flat ring strong magnetic field magnetic separator, SHP wet strong magnetic field magnetic separator, and vertical ring wet strong magnetic field magnetic separator.

Photo-oxygen purification equipment

The equipment uses nano-semiconductor photocatalytic technology with independent intellectual property rights, which can remove common waste gas pollutants such as VOCs, acid-base gases, inorganic gases, and effectively deodorize. In addition, the equipment also uses active oxygen pretreatment technology, using microwave ultraviolet lamps to produce a variety of active oxygen molecules, which greatly improves the efficiency of back-end photocatalysis. Most importantly, the equipment outlet section is also equipped with an ozone removal module, which can reduce the ozone generated by the equipment and reduce the impact of ozone on the surrounding environment.

How much does it cost for you to carry out the smallest scale lithium battery recycling process?

If you want to recycle 2,000 kg of lithium batteries per hour, you will need about $14,000. Let me explain it to you in detail.

- 1

For small-scale lithium battery recycling projects, you need to choose the right equipment. In this regard, the YS-300 shredder and YS-400 hammer crusher provide affordable options at a price of about $2,000 each, designed to handle the initial crushing needs of the battery.

- 2

Further screening can be completed by the YS-300 airflow screener and YS-600 specific gravity screener, which meet different sorting requirements at a price of about $3,000 and $4,300 respectively, thereby ensuring the effective separation of materials.

- 3

In addition, in order to ensure the cleanliness of the working environment and meet safety standards, the YS-300 pulse dust collector provides a solution for removing dust generated during the operation at a price of about $2,000. Overall, the combination of these equipment provides a relatively complete set of technical support for small-scale lithium battery recycling, which makes it a good balance in both economy and efficiency.