An electronic waste shredder is a professional machine used to crush and process waste electronic equipment. As the replacement of electronic products accelerates, the amount of electronic waste (such as discarded mobile phones, computers, televisions, printers, etc.) is increasing. People have found that it has immeasurable economic benefits and can solve environmental pollution and achieve resource recycling. Therefore, the design of the electronic waste shredder is to solve this problem. Through the efficient tearing and crushing process, electronic waste of different sizes and shapes is converted into smaller fragments, which is convenient for subsequent classification, recycling, and processing.

What are the main features of our e-waste shredders?

There are many advantages to our e-waste recycling facility, and I have summarized some of them for you below.

- 1

High efficiency

Can quickly process large amounts of e-waste and improve recycling efficiency.

- 2

Wide applicability

Can process all types of e-waste, including hard drives, mobile phones, computers, TVs, etc.

- 3

Environmental protection

Reduces the pollution of discarded electronic products to the environment and reduces resource waste by recycling valuable materials.

- 4

Safety

Professionally designed shredders are usually equipped with safety protection measures to ensure the safety of the operation process.

- 5

Customizability

The size, power and function of the shredder can be customized according to different processing needs.

How does an e-waste shredder work?

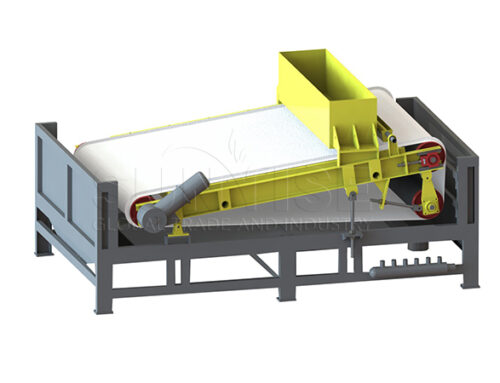

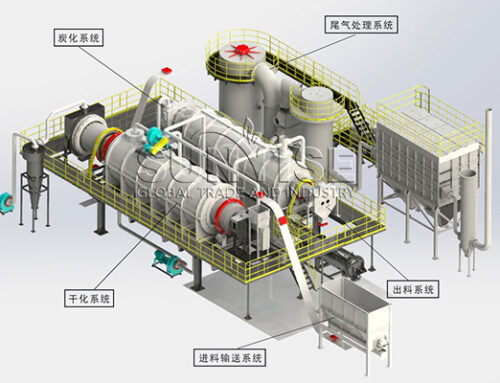

Our e-waste shredders usually consist of a feeding system, a shredding system, and a discharging system. When working, the e-waste is put into the feeding port, and the high-speed rotating blades in the shredding system tear the e-waste into small pieces. These shredded small pieces are discharged through the discharging system, and can then be further sorted and recycled.

What are the differences, advantages and disadvantages of different types of e-waste shredders (such as single-axis, double-axis, and four-axis shredders)?

E-waste shredders can be divided into single-axis, double-axis, and four-axis types according to the number and structure of the shredding shafts, each with its own characteristics, advantages and disadvantages, and applicable occasions.

Single-axis shredder

Single-axis shredders are known for their simple structure and convenient operation and maintenance, especially the low cost of blade replacement, which is very suitable for shredding tasks for large or soft materials. However, it is relatively low in shredding efficiency, sometimes it may take multiple treatments to reach the required material size, and its ability is also limited when dealing with hard or tough materials.

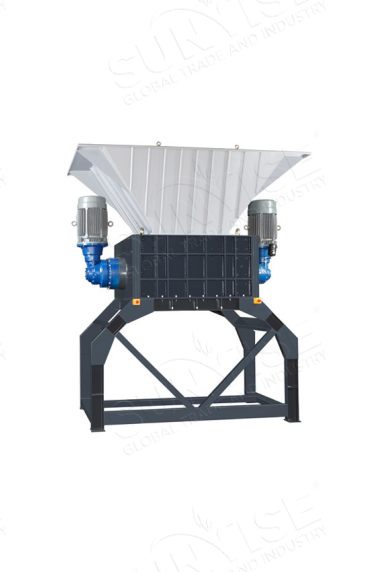

Double-shaft shredder

The double-axis shredder provides shear forces from two directions for material shredding through blades installed on its two parallel rotating shafts. This unique design allows it to show efficient shredding capabilities when dealing with mixed materials, especially for harder or tougher materials. Thanks to the shear force generated by the double-axis rotation, it is more suitable for crushing larger materials. However, the structure of this machine is relatively complex, resulting in high maintenance and blade replacement costs, and also generates large energy consumption during operation.

Four-axis shredder

The four-axis shredder stands out for its design of four rotating axes, two pairs of which usually rotate at different speeds, providing more powerful tearing and shearing forces. Although it can handle hard and complex materials, its complex structure, high cost and professional maintenance requirements constitute the main limitations, and it usually requires professional operation and maintenance.

Leave A Comment

You must be logged in to post a comment.