In the process of lithium battery recycling, the discharge problem is the first problem to be solved. Due to the different reasons and times of lithium battery scrapping, the battery capacity in the lithium battery is also different. In addition, if the lithium battery is not discharged during crushing, it is easy to cause flash explosions and other phenomena. This has a great impact on equipment production. Our lithium battery discharge techniques are very mature. Because we have many successful experiences, professional equipment, and a highly educated team.

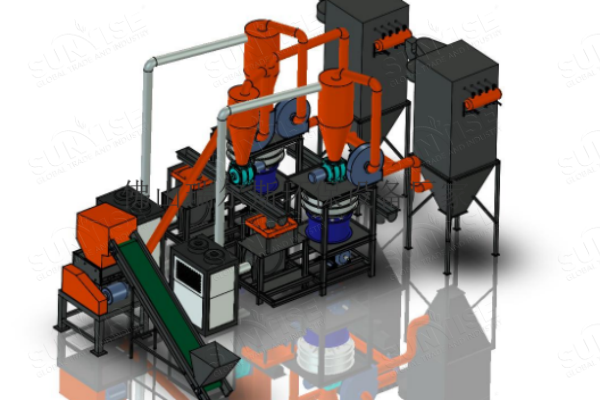

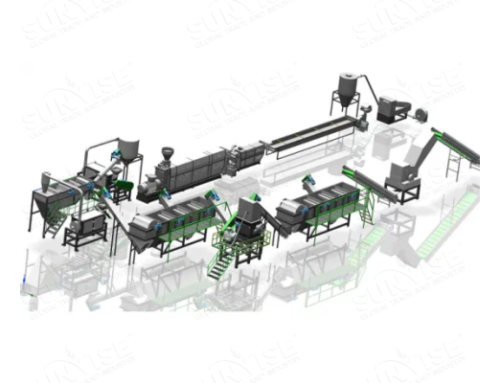

Lithium battery discharge and cooling process

How to discharge lithium batteries? First, you can use a conveyor to feed the charged lithium-ion batteries into the equipment for discharge. Then, the discharged batteries will fall directly into the discharge cooling box, which is equipped with a mesh belt conveyor for material transportation. In addition, during the transportation process, the materials will pass through the water tank, and the battery will be discharged and cooled by water. For lithium batteries of different shapes (soft pack, cylindrical, etc.), discharge devices with different processes can be made.

Leave A Comment