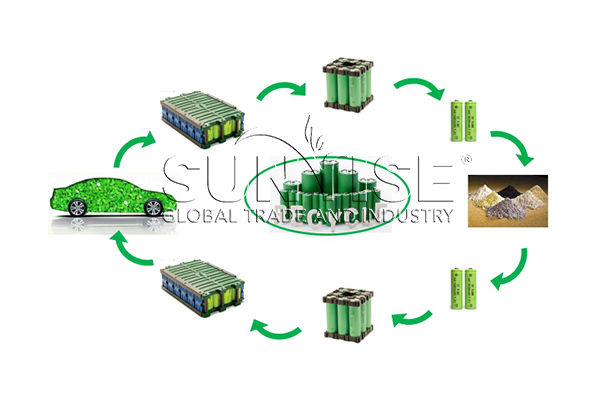

How to recycle car batteries and what can you do with them?

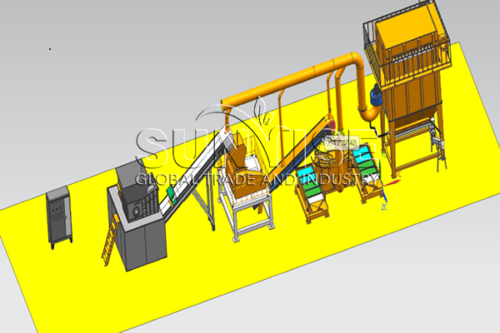

In comparison with lithium battery recycling equipment, the car battery recycling machine only has an additional module disassembly device. By using the following five car recycling machines and performing the following operations, the car battery recycling process can be completed.

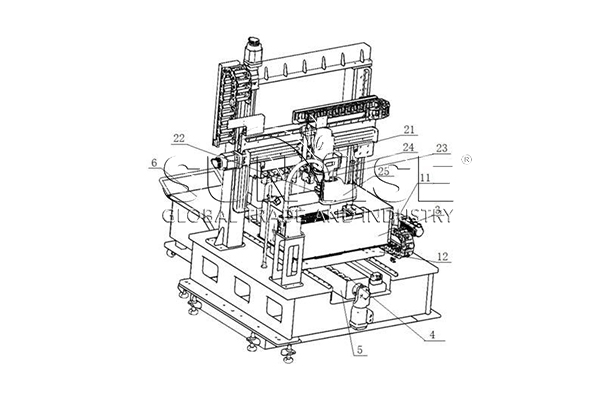

Module disassembly equipment

Firstly, start by placing the module to be disassembled onto the double speed chain line of the module disassembly equipment. Secondly, manually cut the FPC and cache station. Subsequently, use the electric drill to drill the rivets of the module in order to loosen the fixed rivets of the side plate. Afterwards, manually remove the side plate of the module and place the end plates in the designated position. Additionally, detach the surface pad attached to the battery cell. Thirdly, utilize the auxiliary cutting mechanism to cut the connecting sheet on the module. Lastly, transport the single battery cell to the module sorting conveyor line.

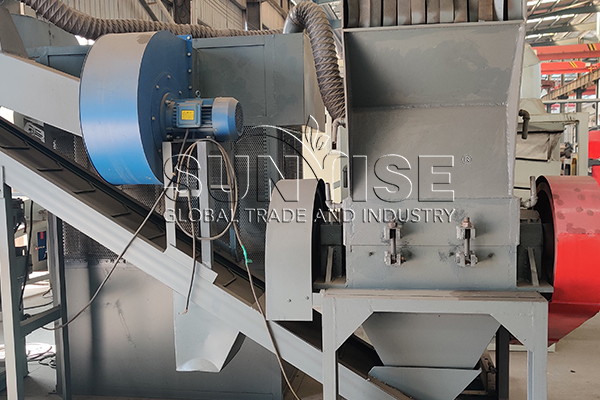

Car battery crushing machine

Firstly, the conveyor sends the scrapped car batteries to the primary crusher of the car battery recycling machinery for crushing. Secondly,The conveyor then transports the chopped materials to the secondary crusher for secondary crushing. In addition, the secondary crushed materials are transported by a conveyor. Finally, the machine also includes magnetic separation equipment to separate the iron from the material.

First of all, the conveyor transmits the sorted materials into the air flow sorter.Moreover, the induced draft fan and cyclone feeder separate the diaphragm paper in the positive and negative electrodes. Besides, the third-level crushing machine processes the sorted positive and negative electrode sheets. Finally, the material is finely crushed to about 20 mesh.

In addition, there are the following two processes.

Secondary crushing

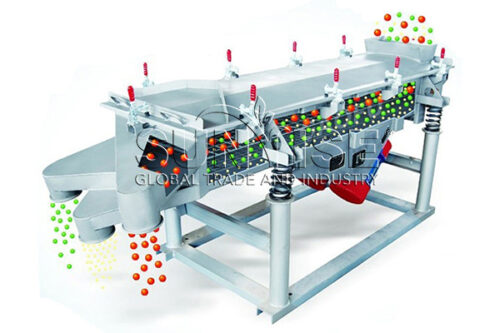

Firstly, the crushed materials enter the linear screen through the conveyor to screen out the black powder. Afterwards, the successfully ground copper and aluminum enter the specific gravity separator through the conveyor to separate copper and aluminum. Subsequently, the remaining materials enter the grinder again. Finally, processing them once more.It successfully obtained the separated copper and aluminum through the use of a linear screen and specific gravity separator.

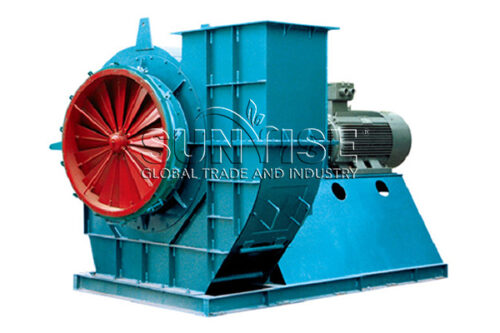

Dust removal equipment

Firstly, the negative pressure system brings all the ultrafine dust into the pulse dust collector for collection. Immediately afterwards, the filtered exhaust gas will continue to be sent to the exhaust gas treatment equipment by the negative pressure system for air purification. Finally, it is discharged after it reaches the national emission standards.

11 types of car battery recycling machines and how they work.

The module disassembly equipment uses mechanical, physical, thermal treatment, and chemical treatment methods to disassemble and separate the components and materials of the module. This process allows for recycling and reuse of the different parts. Furthermore, different equipment and disassembly targets require different solutions.

The magnetic separator, which can sort different magnetic substances, allows for the purification of ore or the recovery of useful minerals. It can effectively separate iron.

The material is ground through grinding media to break it into powdery or fine-grained material. In addition, the sieve separates the materials that meet the requirements. This process is particularly important when grinding copper and aluminum.

The sand discharge tank can produce different floating speeds depending on the material density. This gravitational effect is used for sorting materials, such as copper and aluminum.

Bulk materials are consolidated, stored, and transported to improve material management efficiency and operational efficiency. This is achieved through the efficient handling and transportation of materials.

This equipment can not only perform low-temperature processing of items by controlling the heating system and temperature control system, but our company has equipped it with heat insulation and cooling systems that can also perform low-temperature processing of items.

How can you reduce pollution when recycling car batteries?

These car battery recycling machine of ours can help you solve this problem.

Activated carbon adsorption box

This car battery recycling machine utilizes the characteristics of activated carbon to adsorb pollutants in the gas to the surface of the activated carbon, thus achieving a purification effect. Dust removal during car battery recycling.

Oil fume purification equipment

By utilizing a variety of treatment methods in combination, this equipment has the capability to effectively eliminate pollutants present in oil fumes, ultimately leading to a purification effect. This process works to purify oil fumes, enhancing the overall quality of the air and promoting a healthier environment.

What makes our car battery recycling equipment better than other companies’ equipment?

Efficient performance

Our automotive battery recycling equipment has efficient performance and processing capacity, allowing it to swiftly and accurately dispose of large quantities of used batteries. As a result, the recycling process is not only efficient but also completed in a timely manner, ensuring that the operation runs smoothly and effectively.

Versatility

In addition, our automotive battery recycling equipment is equipped with a variety of processing and sorting functions. For instance, it has the capability to sort, break, separate, and recycle different types of batteries. This not only enhances resource recovery but also ensures efficient and effective recycling processes.

Safety and environmental protection

Our automotive battery recycling equipment may have high standards of safety measures. Furthermore, it also incorporates environmental protection technology to ensure the safety of the operator and the environmental protection of the recycling process. Additionally, the equipment is designed to meet stringent safety regulations and environmental standards, making it a responsible choice for sustainable recycling practices.

Customizable and flexible

Our automotive battery recycling equipment can be customized in design and operated flexibly, thus allowing it to adapt seamlessly to different types and specifications of used battery recycling needs. Additionally, the equipment is versatile , making it a reliable solution for businesses with diverse recycling requirements

If you are interested, please feel free to contact us. In addition, our company will be happy to provide you with more detailed information and support.