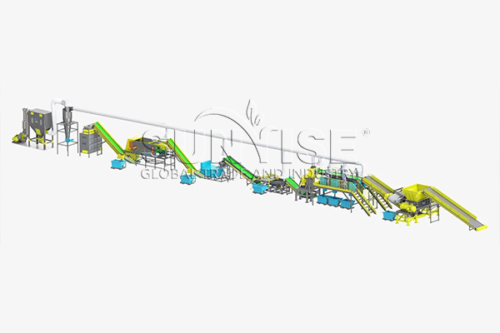

As a matter of fact, the PCB dismantling machine is a device specifically designed to handle electronic circuit boards. In addition, the electronic circuit board is the core component of electronic products. Because it contains a large number of valuable components and materials. Such as chips, capacitors, resistors and so on. In summary, by using the PCB dismantling machine, we can disassemble the electronic circuit board, thus recovering valuable components and materials.

How does our pcb dismantling machine work?

These are the two components of our pcb diamantling machine.

Circuit board dismantling machine

First, the PCB disassembly machine uses electrical/liquid heating to 150 ° C, thus processing the electronic components in the circuit board. In addition, its frame is fixed to the heating tube. So it can drive the drum with a decelerating motor. Second, melting tin at 380°C causes the tin element to fall off. Finally, the vibrating screen separates the tin from the small parts, so the large parts and substrate can be removed after cooling.

Induced Draft Fans

This pcb dismantling machine usually has an air inlet through which the surrounding air is sucked into the interior of the machine. When the air is sucked in, the internal device of the machine will rotate or swing to accelerate the air and push it towards the induced draft fan. The outlet creates an air current or wind. Channels such as pipes and air outlets can transport or distribute the exhausted airflow.

How to dispose a circuit board using our pcb disassembly equipment?

Here are the six steps you need to take with our pcb disassembly equipment.

Circuit board disassembly machine

Two types of electric heating liquefied gas heating are used to control the internal temperature at about 150°C to loosen the tin on the circuit board. As the disassembly machine rotates and the circuit board rubs against each other, the circuit board Rub against the cylinder wall, and the electronic components will fall off as the host runs.

Smoke dust cover

Add a smoke and odor collection cover on the disassembly machine to facilitate the collection of smoke and odor to meet environmental protection standards.

Water spray tower

Use water spray to purify the smoke and dust particles passing through the induced draft fan.

Activated carbon adsorption box

Absorb and deodorize the flue gas purified by water spray.

Plasma purifier

The flue gas purified by the activated carbon adsorption box is then colorless, so as to achieve environmental protection indicators.

Induced draft fan

Collects and discharges the filtered gas.

How can you reduce pollution in our dismantling process?

You can use the following environmental protection equipment in the PCB disassembly process.

Flue gas dust cover

Add a smoke and odor collection cover to the circuit board disassembly machine to facilitate the collection of smoke and odors to meet environmental protection standards.

The water spray tower is also called a spray tower, dust removal tower, desulfurization tower, denitrification tower, etc

It separates pollutants (dust-containing gases or harmful gases) in the gas and converts them into harmless substances to achieve the purpose of purifying the gas. It belongs to the differential contact counter-flow principle.

Activated carbon adsorption box

This pcb dismantling machine uses the characteristics of activated carbon to adsorb pollutants in the gas to the surface of the activated carbon to achieve a purification effect.

Plasma purifier

Low temperature plasma can process volatile organic compounds. Under the action of an applied electric field, a large number of energetic electrons produced by dielectric discharge bombard pollutant molecules, causing them to ionize, dissociate, and excite, thus triggering a series of complex physicochemical reactions.So that it can actively degrade and remove pollutants.

What are the advantages of our pcb disassembly equipment?

I will elaborate on the advantages of our pcb disassembly equipment from four points.

Why using our pcb disassembly equipment can ensure profitability and resource sustainability?

These four aspects demonstrate the importance of using our pcb disassembly equipment for sustainable development.

How can you use pcb dismantling equipment to ensure certain safety?

First of all, if you use PCB disassembly equipment, you must pay attention to wearing personal protective equipment. At the same time, it is important to carry out the disassembly under ventilated conditions. In addition, we must ensure the safety of the operator and standardize the operation. In addition, fire prevention measures are essential. Finally, after dismantling the waste, one must properly sort and dispose of it. Because this not only avoids environmental pollution but also endangers people’s health.