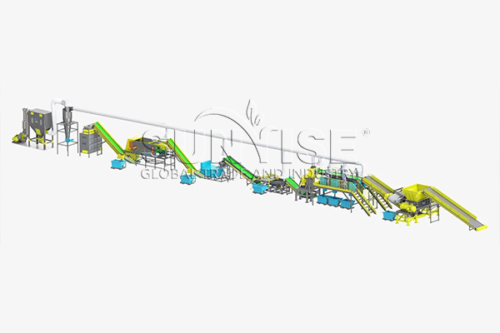

Copper separator is a device for separating and purifying copper materials. Its role is not only to separate impurities in the mixed copper material, but also to separate copper and other metals of different densities. Therefore, high purity copper can be obtained. Moreover, this is of great significance for the application of copper materials in electronic, electrical and other fields. In addition, through the use of copper sorting machine, resource recovery and environmental protection can be achieved, reducing the consumption of natural resources.

How does our copper sorting machine work?

The working principle of the copper sorting machine is to use the differences in different physical properties of materials to sort. Usually, copper sorting machines use different sorting methods such as gravity sorting, vibration sorting and air flow sorting.

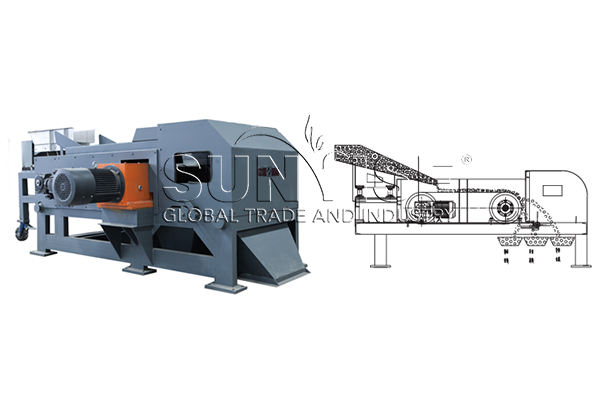

Gravity separation

During the gravity separation process, the copper separator separates impurities of different densities from copper by adjusting the angle and slope of the incline. The density of copper is higher, while the density of impurities is lower. By gravity, the impurities are separated out, while the copper is deposited at the bottom.

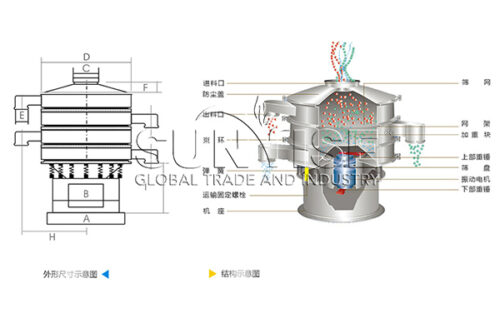

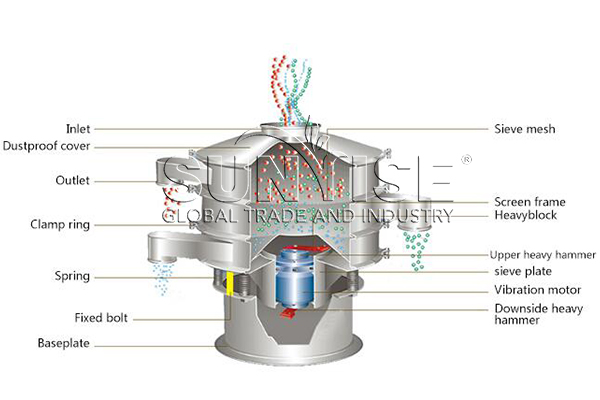

Vibration separation

During the vibration sorting process, the copper sorting machine uses the power of vibration to stratify the mixed copper materials. Because copper is denser, it settles to the bottom while impurities float to the top. By adjusting the vibration frequency and amplitude, a more precise sorting effect can be achieved.

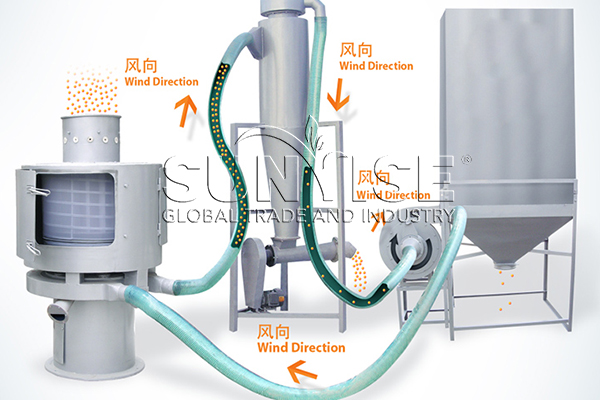

Air separation

During the airflow separation process, the copper sorting machine uses the power of airflow to separate light impurities in mixed copper materials from heavy copper. By adjusting the speed and pressure of the air flow, the flight trajectory of impurities can be controlled to achieve sorting.

It can apply individual or combined sorting principles to achieve more efficient copper sorting. The specific sorting method used depends on the nature of the material and the sorting requirements.

What are the costs and energy consumption of a copper sorter? Is there any solution?

The cost and energy consumption of copper sorting machine vary depending on their model, size, technology and brand. Generally speaking, high-performance, large-scale copper sorters cost more, while small, low-energy copper sorters cost less.

When considering costs, the main expenses of the copper sorting machine include the initial equipment price. Additionally, transportation, installation, and maintenance costs are important factors.In addition, the cost of additional equipment (such as conveyor belts, vibrators, etc.) supporting the copper separator needs to be considered.

When it comes to energy consumption, a copper sorter’s energy use primarily relies on the sorting process. This includes electricity or fuel usage.Vibration and airflow sorting have lower energy consumption because these sorting methods do not require a lot of energy. Additionally, these methods can help optimize the cost of the copper sorter.Gravity sorting may require a certain amount of energy to provide the tilting force of the incline.

To optimize the cost and energy consumption of the copper sorter, one can consider the following options.

In order to optimize the cost and energy consumption of the copper sorting machine, it is essential to select appropriate equipment. Additionally, implementing relevant management measures based on the specific circumstances is crucial. This can lead to improved efficiency and reduced operational expenses.