Waste battery recycling plants play a vital role not only in protecting the environment but also in the utilization of resources. General waste battery recycling mainly includes lithium battery recycling, solar panel recycling, and mobile phone battery recycling. It is worth mentioning that the Brazilian government has introduced relevant policies and regulations. For example, Brazil promulgated the “Electronic Waste Management Law” in 2010. It stipulates the principles, objectives, and division of responsibilities for electronic waste management. Therefore, it is conducive to the development of waste electronic product recycling plants in Brazil. On March 21, 2024, customers from Brazil consulted us about battery recycling plants, and finally, we reached a pleasant cooperation.

Three types of battery recycling equipment.

In response to customer needs, we have carefully designed a recycling system that can efficiently process up to 700kg of batteries per hour, while also taking into account the requirements of a wide processing range and reasonable price. Below are the e-waste recycling equipment options we offer our customers to ensure your battery recycling process is both efficient and environmentally friendly.

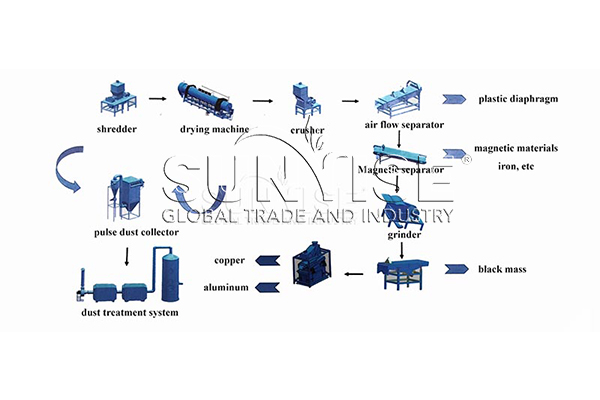

How a waste battery recycling plant works?

This is a specific plan we customize based on the customer’s specific situation.

Leave A Comment