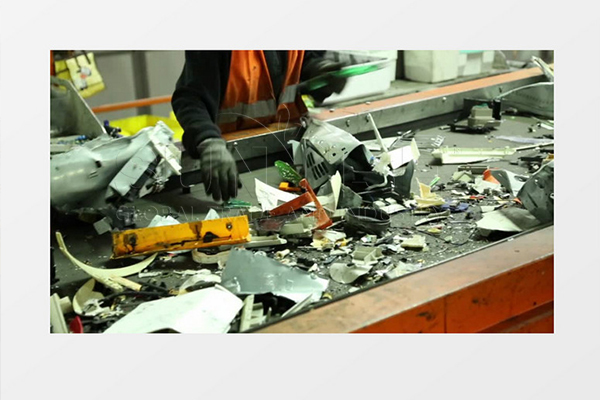

As a product of modern scientific and technological development, electronic products play an extremely important role in our lives, but with it comes the massive generation of electronic waste. Electronic waste not only occupies a large amount of resources and space but also poses a serious threat to the environment and human health. In order to solve this problem, electronic waste recycling equipment came into being and plays an important role. If you want to recycle e-waste more efficiently, then you need to know these things about e-waste recycling equipment.

What are the electronic waste recycling equipment?

Electronic waste recycling equipment includes three categories: crushing equipment, screening equipment, and dust removal equipment. Crushing equipment includes single-shaft shredders, double-shaft shredders, and hammer crushers. Screening equipment includes airflow screens, specific gravity screens, linear screens, and circular screens. The most important dust removal equipment includes not only activated carbon adsorption equipment and pulse dust collectors but also water spray towers and plasma dust removal equipment.

How do electronic waste recycling facilities ensure safety during the processing process?

Equipment design

The safety of the operator should be fully considered when designing the equipment. In addition, the equipment should have an emergency stop switch so that the equipment can be stopped quickly in an emergency.

Operation guide

The equipment should be equipped with a detailed operation guide. At the same time, some possible risks should also be pointed out in the operation guide, and the operator should be guided on how to avoid them.

How efficiently do e-waste recycling facilities operate?

The efficiency of e-waste recycling equipment depends mainly on its design and operation. Ideally, these equipment can quickly and efficiently separate and recover various valuable materials in e-waste.

Equipment types

There are many types of e-waste recycling equipment, and different equipment has different recycling efficiencies. For example, some equipment specifically designed to separate heavy metals may be more efficient than general-purpose equipment.

Operation method

The operation method of the equipment will also affect its operating efficiency. For example, fully automated equipment that performs all operations by machine is more efficient than equipment that requires human intervention.

Leave A Comment