Discharging of used lithium batteries refers to the process of completely releasing the stored electrical energy in used lithium-ion batteries before disposal. In addition, this process is usually carried out under safe and controlled conditions to minimize the charge inside the battery to reduce potential safety risks and environmental hazards.

How to discharge a lithium battery?

You can use the following methods to handle lithium batteries, including soft-pack and cylindrical batteries. However, you need to perform corresponding discharge treatment according to their different characteristics.

Is there any other way to improve the quality of discharge?

What equipment is needed to discharge lithium-ion batteries?

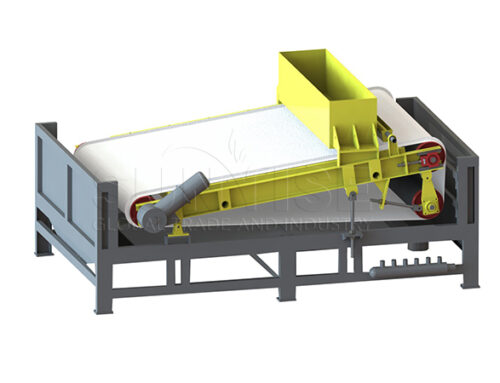

Needle discharge equipment

You can feed the charged lithium-ion battery into the equipment through the conveyor. Then, the lithium-ion battery is discharged through the needle roller. Finally, the gap between the needle roller and the feed table can be adjusted to meet the discharge requirements of different types of lithium-ion batteries.

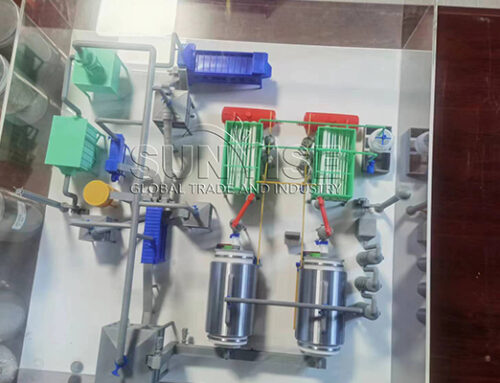

Spraying equipment

You need to feed the lithium-ion battery after needle discharge into the mesh belt conveyor. In addition, the spray device is used to cool down during the conveying process. The lower part of the conveyor is equipped with a water tank. It can be recycled.

Leave A Comment

You must be logged in to post a comment.