Circuit board recycling equipment is crucial in electronic waste recycling. Its functions include resource recovery, electronic waste management, and environmental protection treatment. The main equipment and technologies include crushers, screening equipment, magnetic separation equipment, gravity separation equipment, and electric separation equipment. These equipment together improve resource utilization and reduce environmental pollution. More importantly, recycling electronic waste can recover many precious metals, which have economic value. If you use our electronic waste recycling equipment, then your electronic waste recycling rate will also increase.

What equipment is needed for circuit board recycling?

Circuit board recycling equipment is used to extract valuable metals and materials from scrap circuit boards. Our circuit board recycling equipment is very professional.

What equipment do you use to improve your recycling rate?

If you want to increase your recycling rate, please use our equipment below.

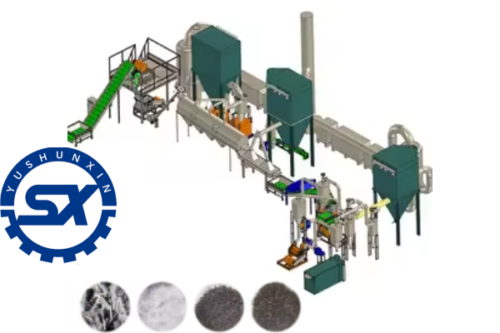

This equipment uses PLC to control the uniform feeding and coordinated operation of the entire production line. In addition, it uses three-stage crushing, and the processing capacity can reach 1000kg per hour. And you can use it to crush the broken circuit boards to about 20 mesh.

High-voltage electrostatic separation

You can use high-voltage electrostatic separation to separate the small copper powder and resin contained in the tailings after the gravity separator. This can improve the recycling efficiency. In addition, the output of our equipment is about 1-10 tons/day.

What is the price of circuit board recycling equipment?

The price of circuit board recycling equipment varies depending on factors such as its type, scale, degree of automation and production capacity.

2000kg/h pcb recycling equipment price

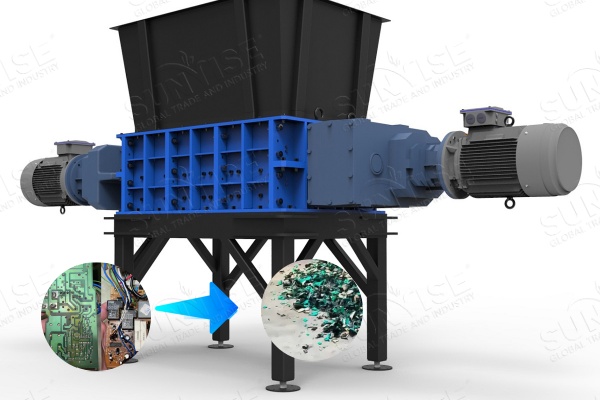

If you want to process 2000kg of PCBs per hour, this kind of small-scale recycling production line. Then I recommend you buy a YS-300 shredder, which costs about $3000. A YS-500 circuit board crusher, which costs about $2000. In addition, a YS-300 analyzer, which costs about $2000. A YS-300 gravity separator, which costs about $4000. Most importantly, a YS-300 pulse dust collector costs about $2000. So in total, you need to spend about $13,000.

4000kg/h pcb recycling equipment price

For your medium-scale recycling production line (processing 4,000 kg of PCB per hour), we recommend the following equipment: shredder model YS-600, priced at about $6,000; circuit board crusher model YS-1000, priced at about $4,000; analyzer model YS-600, priced at about $4,000; gravity separator model YS-600, priced at about $8,000; pulse dust collector model YS-600, priced at about $4,000. The total cost of the above equipment is about $26,000. These equipment will provide you with efficient and reliable PCB recycling processing capabilities, ensuring that you can achieve the best recycling results at the lowest cost.

7000kg/h pcb recycling equipment price

For large-scale recycling production lines (processing 7,000 kg of PCB per hour), we recommend the following equipment: shredder model YS-1000, price about $10,000; circuit board crusher model YS-1500, price about $7,000; analyzer model YS-1000, price about $7,000; specific gravity separator model YS-1000, price about $14,000; pulse dust collector model YS-1000, price about $7,000. Combined with the prices of the above equipment, the total cost is about $45,000.