Avada Energy 1234 Avada Avenue, Avadaville, 11221

Monday – Saturday: 8am – 6pm

Sunday: 11am — 4pm

Request a detailed estimate

Frequently Asked Questions

As the demand for lithium batteries rises, so does the need for effective recycling solutions. Understanding the price of a lithium battery recycling line is crucial for businesses considering this investment. Let’s delve into the various factors that influence the cost and explore specific pricing and equipment configurations based on different production capacities.

What Factors Determine the Price of a Lithium Battery Recycling Line?

Three primary factors influence the price of a lithium battery recycling line: capacity, equipment, and configuration.

How Much Does a Lithium Battery Recycling Line Cost?

The price of a lithium battery recycling line can range from $5,000 to $21,000. This wide range reflects different capacities and equipment configurations.

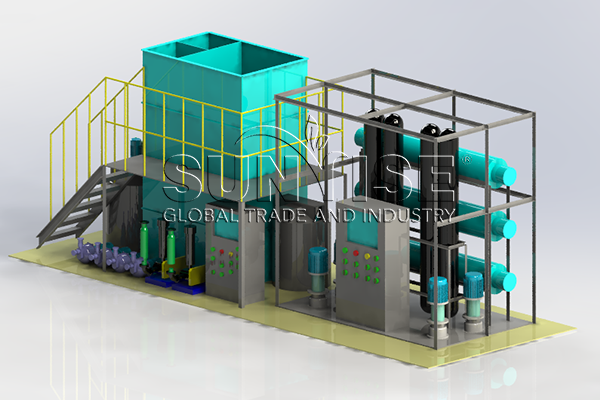

For a recycling line with a capacity of 200-300 kg/h, the price generally falls between about $5,000 to $11,500. This setup typically includes:

Shredder: For initial size reduction of the batteries.

Separator: To segregate different materials such as metals and plastics.

Purification System: To refine and purify the recovered materials.

This configuration suits small to medium operations, offering a balance of efficiency and cost.

A recycling line designed for 300-500 kg/h capacity ranges from approximately $11,500 to $21,000. This setup often includes:

High-Capacity Shredder: Capable of handling larger volumes of batteries.

Advanced Separation Technology: For higher efficiency in material segregation.

Comprehensive Purification System: Ensuring high purity of recovered materials.

Automated Control Systems: For enhanced process monitoring and control.

This configuration is ideal for larger operations requiring high throughput and efficiency.

In conclusion, the price of a lithium battery recycling line depends on capacity, equipment, and configuration. For small to medium operations, a 200-300 kg/h line costs between $5,000 and $11,500. Larger-scale operations may opt for a 300-500 kg/h line priced between $11,500 and $21,000. Understanding these factors helps businesses make informed decisions, investing in the right recycling line to meet their needs. This not only contributes to environmental sustainability but also offers economic benefits. If you want to know 1000kg/h lithium battery disposal, you can also contact us.

Lithium-ion battery recycling machinery recycles waste batteries through pretreatment, crushing, sorting, and chemical treatment. In addition, these machines help separate and extract valuable metals such as lithium, cobalt, and nickel from batteries, reduce resource mining, and improve resource utilization. More importantly, recycling not only reduces environmental pollution but also has economic benefits. If you are interested in lithium-ion battery recycling machinery, the choice of lithium-ion battery recycling machinery manufacturers is also very important. Our company specializes in recycling electronic waste and has won the trust and love of customers.

How do you choose the right lithium-ion battery recycling machinery manufacturer?

Choosing the right lithium-ion battery recycling machinery manufacturer is a process that requires comprehensive consideration of multiple factors. Here are some key considerations to help you make an informed decision.

Yuansheng has more than ten years of experience and qualifications in lithium-ion battery recycling. And we have received wide praise and trust in the cases we cooperate with customers. This is all due to our professional team and high-quality electronic waste recycling equipment. If you are interested in us, please feel free to contact us.

Your Content Goes Here

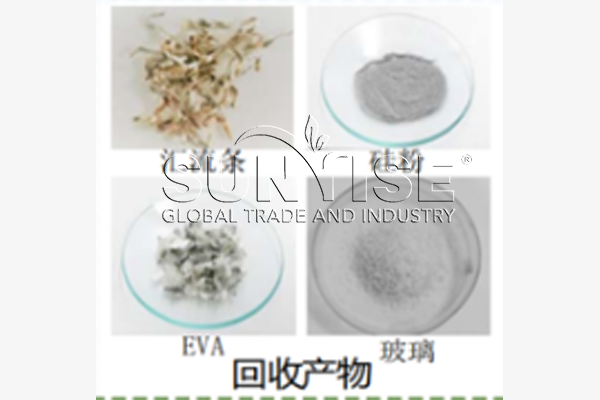

As the solar industry expands, solar panel recycling has become crucial to solve the problem of decommissioned panel disposal, protect the environment, and recycle valuable raw materials such as silicon, silver, etc. The recovery process includes pretreatment, separation, chemical treatment, purification, and strict control. This not only helps reuse resources and reduce environmental pollution but also has significant economic value. However, choosing the right solar panel recycling equipment is important. Because this can not only improve recycling efficiency but also save costs.

Four major factors to help you choose the most suitable solar panel recycling equipment Manufacturers.

Contact Us

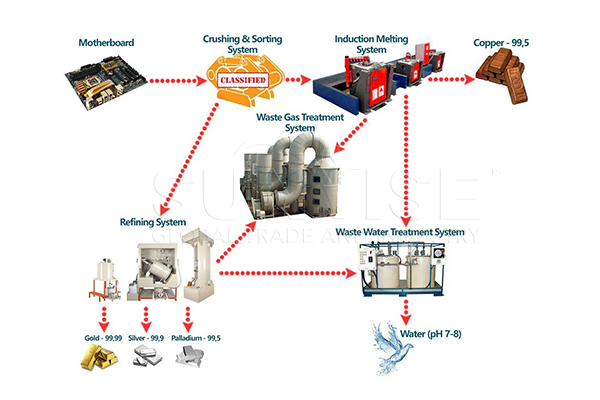

E-waste recycling equipment is a general term for a series of equipment and technologies used to process and recycle waste electronic products. E-waste includes old computers, mobile phones, televisions, refrigerators, and other electronic or electrical equipment. Since these wastes contain valuable metals (such as gold, silver, copper rare metals, etc.) and other reusable materials, you can recycle these materials through a special recycling process and gain economic benefits at the same time. In addition, e-waste recycling equipment usually includes crushers, sorters, magnetic separation equipment, electric separation equipment, dust removal systems, etc., which work together in the pretreatment, crushing, separation, and fine processing of e-waste.

What is the role of electronic waste recycling equipment?

- 1

Resource recycling

Electronic products contain abundant metal resources, such as copper, aluminum, gold, silver, etc., as well as non-metallic materials such as plastics. You can recycle these valuable materials through the processing of recycling equipment, reducing the demand for mining raw materials.

- 2

Environmental protection

If discarded electronic products are not handled properly, heavy metals and harmful substances will leak, causing serious pollution to the soil, water sources and air. Our electronic waste recycling equipment can safely handle these harmful substances, reducing environmental pollution and health risks.

- 3

Promoting economic development

The development of the electronic waste recycling industry can not only create employment opportunities, but also promote the advancement of related environmental protection technologies and equipment, which has a positive effect on economic development.

What are the main technologies of electronic waste recycling equipment?

Contact Us

Waste circuit boards (also called printed circuit boards, PCBs) contain a variety of valuable metals and other materials, so they have a very high recycling value. These metals include gold, silver, copper, aluminum, nickel, and tin, among which precious metals are the most valuable. So how should you recycle scrap circuit boards?

Top 1 recycling method for waste printed circuit boards.

The final product obtained after processing by the PCB circuit board recycling machine is precious metals (90% copper) and resin fiber powder. The metal separated in this way is of high purity and good quality and can be sold directly to the metal trading market, bringing huge economic benefits.

What is the economic benefit of extracting precious metals from waste circuit boards?

The economic benefit of extracting precious metals from waste circuit boards mainly depends on the following key factors.

Contact Us

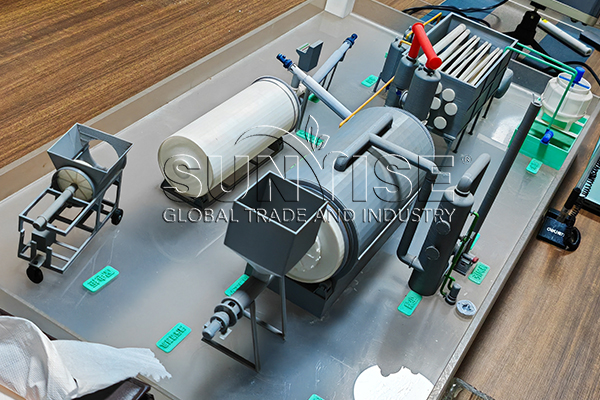

Solar panel recycling equipment plays a key role in the recycling process, achieving efficient resource reuse through automatic disassembly, material separation and recycling, chemical treatment, and purification. The use of crushing, grinding, automation, and intelligent control systems ensures that the recycling process is energy-saving, safe, and environmentally friendly. In addition, our company’s equipment has professional qualifications and certificates, which can complete recycling efficiently and quickly.

What are our company’s solar panel recycling equipment?

4 things you need to consider when buying the right equipment.

Contact Us

Lithium battery recycling and resource utilization are very important. You can obtain rare metals by recycling lithium batteries, save valuable resources, and achieve significant economic benefits. Lithium battery recycling helps achieve sustainable development goals and requires joint efforts from all parties to promote its development. Below I will tell you more about the economic feasibility of recycling lithium batteries.

What factors affect the profitability of lithium battery recycling?

There are many factors that affect the profitability of lithium battery recycling. Below I will introduce some of the main factors.

How can you increase profits from lithium battery recycling?

Technological innovation and process optimization

You can increase metal extraction rates and purity and reduce material waste by employing more advanced recycling technologies, such as new hydrometallurgical and electrochemical recycling. Or introduce automated lithium battery recycling equipment, such as our series of lithium battery recycling equipment model YS-1000, to improve production efficiency and reduce labor costs. Finally, you can also research and apply new recycling methods to improve recycling efficiency and environmental protection levels, which can significantly improve recycling efficiency and overall benefits.

Large-scale operations

You can dilute fixed costs and increase unit recovery profits by expanding the scale of your business. At the same time, cooperation with other recycling companies, manufacturers, and government agencies to establish recycling alliances, share resources and information, optimize collection and transportation networks, and reduce logistics costs can effectively improve recycling efficiency and economic benefits.

Contact Us

Electronic waste contains a large amount of metal resources such as copper, aluminum, gold, and silver, which have high recycling value. Its components such as circuit boards and capacitors can be reused in the manufacture of new electronic products. In addition, if you use our company’s electronic waste recycling equipment, you can increase the recovery rate of precious metals in electronic waste.

4 parts of e-waste that can be recycled.

What materials can you recycle with our e-waste recycling equipment?

Common electronic waste recycling can generally recycle precious metals, such as solar panels, circuit boards, and lithium batteries.

How to improve the recycling rate of electronic waste through our electronic waste recycling equipment?

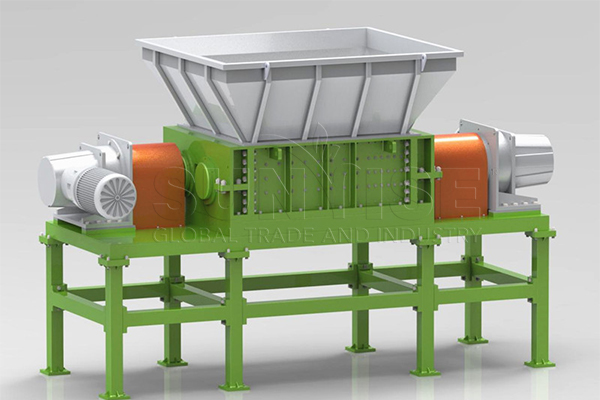

Double-shaft shredder

Our double-shaft shredder can not only adjust the gap between the two shafts according to different materials to produce finer fragments, but also the high-power drive can shred materials to about 20 meshes.

Air flow sorter

If you use it, you can quickly separate materials of different particle sizes, which is more efficient than traditional sorting equipment. In addition, because it adopts air flow separation, the energy consumption is relatively low.

Contact Us

Lithium battery recycling includes resource reuse, reducing the mining of rare metal elements; reducing environmental pollution, avoiding the infiltration of harmful substances into the soil and groundwater; protecting the natural environment and achieving sustainable development; bringing economic benefits and saving resources; preventing safety hazards such as fire or explosion. In general, it has an important impact on environmental protection, resource utilization and safety. Since lithium battery recycling is so important, what are the benefits of recycling lithium batteries for buyers of lithium battery recycling equipment?

What recycling equipment is used for lithium battery recycling?

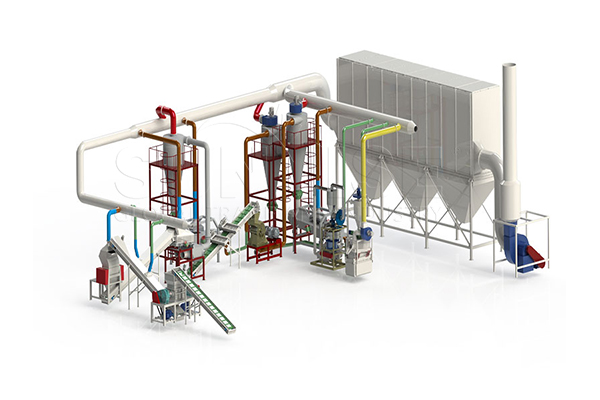

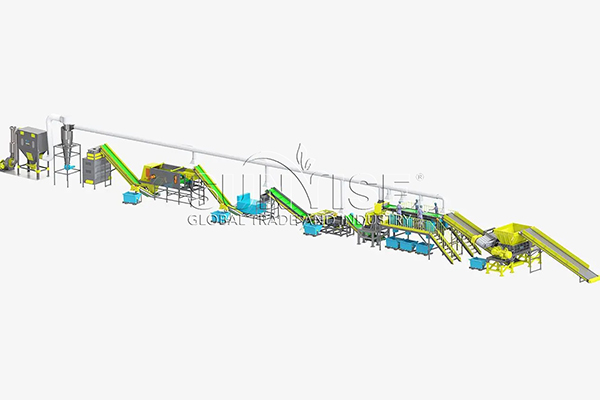

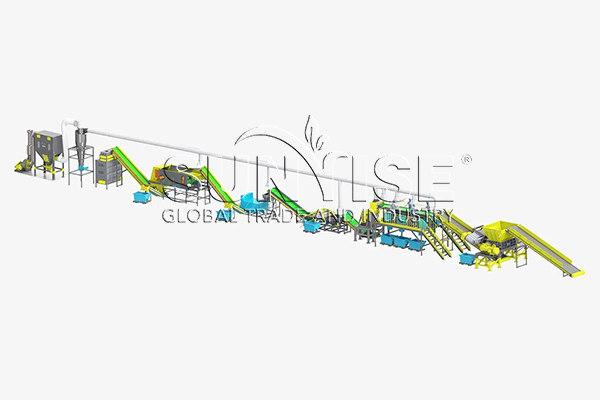

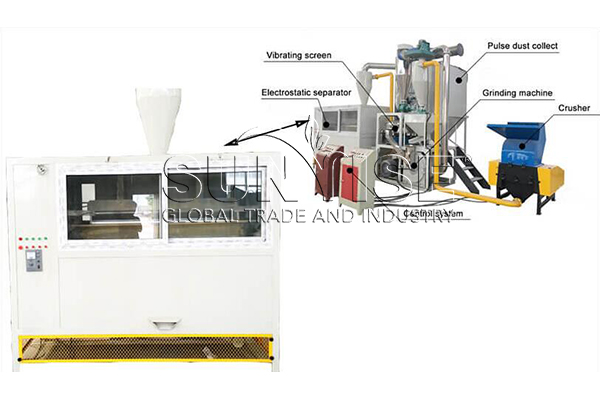

Our recycling process requires the following lithium battery recycling equipment, including crushing equipment, screening equipment, and dust removal equipment. Crushing equipment includes shredders and hammer crushers for secondary crushing. In addition, screening equipment includes air flow screens, specific gravity screens, and magnetic separators. Finally, dust removal equipment includes activated carbon adsorption boxes, plasma purifiers, oil fume purification equipment, and photo-oxygen purification equipment.

What are the benefits of purchasing lithium battery recycling equipment to recycle lithium batteries?

Purchasing lithium battery recycling equipment to recycle lithium batteries has the following benefits.

If you are interested in lithium battery recycling equipment or processes, please contact us.

Contact Us

As a product of modern scientific and technological development, electronic products play an extremely important role in our lives, but with it comes the massive generation of electronic waste. Electronic waste not only occupies a large amount of resources and space but also poses a serious threat to the environment and human health. In order to solve this problem, electronic waste recycling equipment came into being and plays an important role. If you want to recycle e-waste more efficiently, then you need to know these things about e-waste recycling equipment.

What are the electronic waste recycling equipment?

Electronic waste recycling equipment includes three categories: crushing equipment, screening equipment, and dust removal equipment. Crushing equipment includes single-shaft shredders, double-shaft shredders, and hammer crushers. Screening equipment includes airflow screens, specific gravity screens, linear screens, and circular screens. The most important dust removal equipment includes not only activated carbon adsorption equipment and pulse dust collectors but also water spray towers and plasma dust removal equipment.

How do electronic waste recycling facilities ensure safety during the processing process?

Equipment design

The safety of the operator should be fully considered when designing the equipment. In addition, the equipment should have an emergency stop switch so that the equipment can be stopped quickly in an emergency.

Operation guide

The equipment should be equipped with a detailed operation guide. At the same time, some possible risks should also be pointed out in the operation guide, and the operator should be guided on how to avoid them.

How efficiently do e-waste recycling facilities operate?

The efficiency of e-waste recycling equipment depends mainly on its design and operation. Ideally, these equipment can quickly and efficiently separate and recover various valuable materials in e-waste.

Equipment types

There are many types of e-waste recycling equipment, and different equipment has different recycling efficiencies. For example, some equipment specifically designed to separate heavy metals may be more efficient than general-purpose equipment.

Operation method

The operation method of the equipment will also affect its operating efficiency. For example, fully automated equipment that performs all operations by machine is more efficient than equipment that requires human intervention.

Contact Us

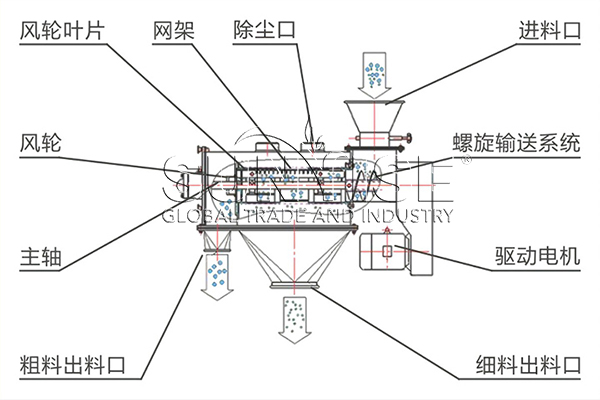

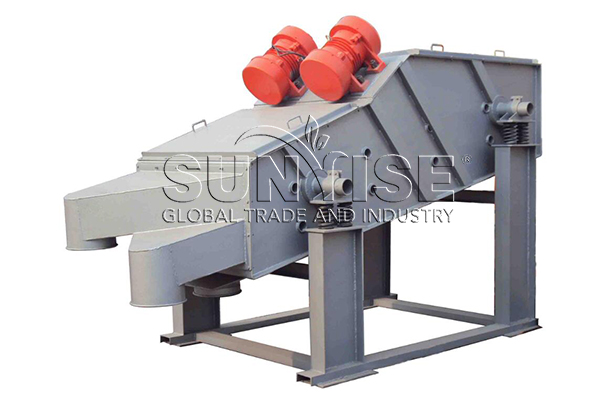

What are the basic principles of circular vibrating screen work?

The basic working principle of the circular vibrating screen first comes from the vibration source, which generates vibration force. This force then drives the screen frame to vibrate periodically. Under the influence of this vibration, the material will perform continuous parabolic motion on the screen surface. Then, due to the gravity of the material itself and the vibration of the screen surface, smaller particles will be filtered out through the screen holes. At the same time, the screen surface retains the larger particles. Finally, through this process, we can achieve grading and screening of materials.

What does a circular vibrating screen consist of?

The circular vibrating screen is a complex device. It consists of numerous components. Firstly, it includes a screen frame and a screen mesh. Additionally, there is a vibration source and a damper. A support device is also included in this assembly. Furthermore, the setup comes with a motor and a transmission device.This intricate device doesn’t stop there. It also has a housing and a collection device. Lastly, an adjustment device is included in this assembly. The primary use of this device is to separate granular materials of different sizes. Not only that, it ensures stable operation and efficiency.

What are the advantages of circular vibrating screen?

Circular vibrating screens, due to their large processing capacity, actively process various granular materials. They accurately screen these materials, thanks to their high screening accuracy. In addition, their compact structure makes them suitable for various spaces, while their high vibration intensity ensures efficiency. Furthermore, they have a long service life and consume low energy, actively contributing to environmental sustainability. These screens also facilitate easy screen replacement, enhancing their usability. Finally, boasting a wide range of applications, they actively engage in screening operations.

What are the applications of circular vibrating screens?

Circular vibrating screens are widely used in mining, building materials, metallurgy, chemical industry, food, environmental protection, agriculture, pharmaceuticals, and other fields. They are mainly used to screen various powders, granules, ores, building materials, chemical products, food raw materials, garbage and sewage, etc., is an important equipment in industrial manufacturing and production processes. If you are interested in e-waste recycling equipment or recycling processes, please feel free to consult us.

Contact Us

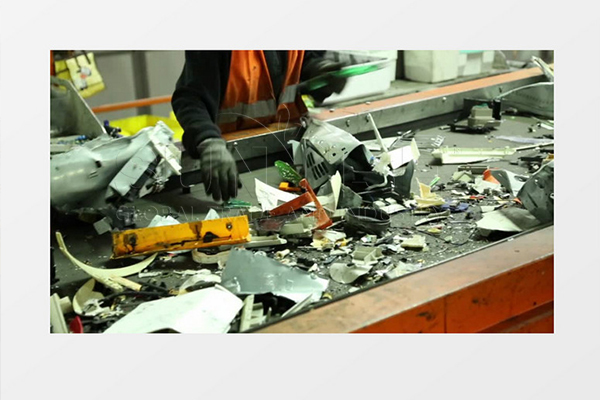

The disposal of waste electronic waste has been concerned. With the acceleration of scientific and technological progress and the increase of people’s dependence on electronic equipment, the scale of waste electronic waste is also expanding day by day. How to deal with these waste electronic waste efficiently and environmentally has become a serious task in front of us.

What are the ways to dispose of e-waste?

There are many ways to recycle electronic waste, such as chemical treatment, electrochemical treatment and so on. However, we recommend recycling, because it can not only reduce environmental pollution, but also bring certain economic benefits. Because used e-waste contains precious metals. For example, waste solar panels can be recycled through our company’s cracking furnaces, color sorters and other electronic waste recycling equipment, and copper can be obtained.

What is the recycling rate of e-waste?

There are many factors determining the recovery rate of e-waste, but the most important is the recovery rate of e-waste recycling equipment. High-quality e-waste recycling equipment can improve the e-waste recovery rate, thereby increasing economic benefits. For example, our company’s two-shaft shredder has the characteristics of large torque and high output, which can break various difficult materials efficiently. As a result, the recovery rate was increased to 90 percent. The recovery rate of an ordinary two-shaft shredder is only 70 percent. All in all, if you want to increase the recycling rate, it is very important to choose the right recycling equipment. If you are interested in our company’s recycling equipment, please ask us.

What is the environmental impact of e-waste?

E-waste is considered hazardous waste because it contains toxic substances, or can produce toxic chemicals when disposed of improperly. Therefore, it has the harm of polluting the environment. In addition, the accumulation of electronic waste not only affects the beauty of the city, but also wastes resources. Because there are a lot of recyclable resources in e-waste. Therefore, recycling through recycling equipment can solve this problem. Moreover, there are also special dust removal equipment in the recovery, such as activated carbon adsorption boxes, spray towers, etc., which can reduce environmental pollution.

Contact Us

The recycling rate of e-waste is an important indicator of the sustainable development of society. Improving the recycling rate of e-waste requires the joint efforts of the government, enterprises and the public. By formulating reasonable policies and regulations, increasing investment, and promoting technological innovation, we can increase the recycling rate of e-waste and promote sustainable development.

What is the recycling rate for e-waste?

Unfortunately, people only recycle 12.5% of e-waste. Global generation of approximately 40 million tons of electronic waste every year. That’s the equivalent of throwing away 800 laptops every second. The average mobile phone user replaces their phone every 18 months. But e-waste accounts for 70% of total toxic waste.

Why are e-waste recycling rates generally low?

There are four main reasons.

Lack of recycling facilities and technology

In some areas, there is a lack of specialized e-waste recycling facilities and technology, making recycling difficult. The high construction and maintenance costs of recycling facilities will also limit the improvement of recycling rates.

Lack of policy support

Some regions and countries lack complete e-waste recycling policies and regulations, as well as relevant incentives and supervision mechanisms, resulting in low enthusiasm among enterprises and individuals for e-waste recycling.

High recycling costs

Because e-waste contains a variety of toxic, harmful substances or materials that are difficult to recycle. So the cost of recycling and disposing of e-waste is high. As a result, some recycling agencies and companies discourage.

Lack of recycling channels

The lack of convenient e-waste recycling channels in some areas prevents consumers from conveniently processing and recycling their electronic products, reducing the recycling rate.

Contact Us

The widespread use of solar energy systems generates waste in the production process. Therefore, it has a bad impact on the environment. At the same time, manufacturers and users have begun to pay attention to the recycling of materials in solar systems. Because it can not only reduce resource consumption but also reduce environmental pollution. This article details the recycling materials of solar energy systems. If you’re interested, read on.

What materials in solar systems can be recycled?

How to recycle solar system materials?

Below is the process flow using our equipment.

Dismantle

You can break down the solar system into components such as cells, glass, and backsheets by manual or mechanical means. In addition, mechanically you can use our deglazing machine and de-framing machine.

Broken

You can shred the disassembled battery cells, back sheets, and other materials through our shredders or shredders for further separation and recycling.

Screening

Our airflow separator, specific gravity separator, and high-voltage electrostatic separator can separate copper, silicon, and EVA glue.

Recycle

Recycle the separated materials.

What are the environmental impacts of recycling solar system materials?

The recycling of solar system materials has a positive impact on the environment. It not only helps to protect resources and save energy, but also reduces environmental pollution, thus promoting sustainable development.

How to improve the efficiency and effectiveness of material recycling in solar energy systems?

Contact Us

With the development of technology, electronic devices play an important role in our lives. However, the massive generation of electronic waste that follows poses a serious threat to the environment and human health. Therefore, proper disposal of electronic devices becomes crucial. So this article explains the importance of proper disposal of electronic equipment and how to take steps to achieve effective e-waste management.

How can you safely dispose of your waste electronic devices?

It is very important to dispose of electronic equipment safely. Here are some suggestions.

Which machines do you can need for disposing of waste electronic equipment?

Our company uses electronic waste dismantling equipment and crushing equipment to deal with waste electronic equipment. In addition, there are screening equipment, magnetic sorting equipment, dust removal equipment and other machines. The corresponding electronic equipment recycling equipment will also vary depending on the type of electronic equipment. If you are interested, you are welcome to consult us in detail.

Which machines do you can need for disposing of waste electronic equipment?

There are two main reasons why e-waste needs to be disposed of properly.

E-waste is potentially valuable to recyclers. Because older electronic devices contain materials like copper, aluminum, lithium and gold. Therefore, recycling these materials minimizes the extraction of original resources and saves energy.

Electronic devices contain toxic substances. Especially lead and arsenic. If it is in a landfill, then these substances will leach out. So it poses a threat to people and wildlife in the area.

What potential threats does e-waste pose to the environment and human health?

The potential threats posed by electronic waste to the environment and human health include: soil and underground contamination, air pollution, health hazards, resource waste, and ecological damage.

Contact Us

Furthermore, we offer different recycling equipment and solutions for various types of e-waste. So our company can fully meet your needs. However, recycling e-waste brings many important benefits. I will introduce the benefits of electronic waste recycling in detail below.

Resource reuse

E-waste contains a large number of valuable rare metals and other resources, such as gold, silver, copper, aluminum, etc. This recycling of waste effectively recycles and reuses a valuable resource. This reduces the consumption and exploitation of natural resources and helps to protect the environment.

Environmental protection

E-waste contains many harmful substances, such as lead, mercury, cadmium, etc. These substances can cause serious pollution to soil, water sources, and air. By correctly recycling and processing these harmful substances, you can avoid the harm they cause to the environment and reduce pollution.

Data security

E-waste may contain a large amount of personal and sensitive data, such as bank account information, passwords, personal photos, etc. By correctly recycling and processing, you can ensure the safe destruction of this data and protect personal information.

In the process of recycling electronic waste, how to ensure the effective recovery and reuse of rare metals and other valuable resources in the waste?

Perfect recycling technology

Because our company has advanced recycling technology, it ensures efficient extraction of rare metals and valuable resources.

High-efficiency recycling equipment

Our company has established a cooperative relationship with a number of electronic waste recycling equipment. More importantly, we focused on improving the efficiency of e-waste recycling, and achieved remarkable results. What’s more, we offer different recycling equipment and solutions for different types of e-waste. Therefore, our company can fully meet your needs.

Improvement of the recycling industry chain

We have a complete e-waste recycling industry chain, including recycling, sorting, dismantling, refining and other links to ensure that resources can be effectively recycled and reused.

Contact Us

The recycling of electronic products is an important task related to resource reuse and environmental protection. Recycling electronic products can promote resource recycling and reduce resource waste and environmental pollution. The best methods for e-waste recycling are therefore of great importance.

What are the most commonly recycled electronic devices?

The most commonly recycled electronic devices include mobile phones and smartphones, computers and laptops, tablets, televisions, and monitors. In addition, household appliances, digital cameras, and camcorders are also frequently recycled.

How to establish advanced recycling facilities and technologies?

The most commonly recycled electronic devices include mobile phones and smartphones, computers and laptops, tablets, televisions, and monitors. In addition, household appliances, digital cameras, and camcorders are also frequently recycled.

Invest in R&D

Invest a lot of money and resources in R&D to develop new recycling technologies and facilities to improve recycling efficiency and quality.

Resource integration and cooperation

Collaborate with other businesses, institutions and governments to share resources, technology and experience. Because such cooperation helps to achieve resource integration and improve recycling efficiency.

Green design and production

Optimize the layout, structure and process of recycling facilities using green design and production concepts. Therefore, you can reduce energy consumption and environmental pollution.

What is the best way to recycle e-waste?

The best way to recycle e-waste is to adopt an integrated e-waste recycling system. For example, the following aspects.

Contact Us

Waste recycling machinery manufacturers play a vital role in the current context of the increasingly serious global e-waste problem. E-waste recycling machinery manufacturers play a key role. Because it not only promotes sustainable development, but also improves e-waste recycling and reduces environmental pollution. Through innovative technologies and equipment, they have injected vitality into the e-waste recycling industry. In addition, they have also contributed to building a resource-saving and environment-friendly society.

Are e-waste recycling machinery manufacturers continuing to invest in research and development to promote the application of new technologies?

The technology and equipment for e-waste recycling are constantly developing and innovating, which can process and recycle e-waste more effectively and reduce the impact on the environment. Therefore, we have been actively investing in research and development and promoting the application of new technologies to improve recycling efficiency and environmental protection levels. Not only does this help advance our industry as a whole, it also better protects the environment and resources.

4 ways to be environmentally friendly with your equipment from e-waste recycling machinery manufacturers.

Exhaust Emissions

Our equipment is equipped with effective exhaust treatment systems that reduce or eliminate harmful gas emissions. For example, by using filters and adsorbents to capture and treat harmful gases such as VOCs (volatile organic compounds), etc.

Wastewater Treatment

Our recycling facilities have appropriate wastewater treatment systems capable of treating and purifying the wastewater generated. This includes removing heavy metals, organic matter and other harmful substances to ensure that wastewater meets discharge standards and does not pollute the environment.

Energy efficiency

Our equipment design focuses on energy efficiency, minimizing energy consumption by optimizing processes and equipment configurations. Thereby, you can achieve this by using energy-efficient equipment, adopting energy-saving measures, and optimizing work processes.

Hazardous material processing

Our equipment can effectively deal with harmful substances in e-waste. Such as lead, mercury, cadmium and other heavy metals. We therefore need to ensure that they are safely isolated and disposed of to prevent impacts on the environment and human health.