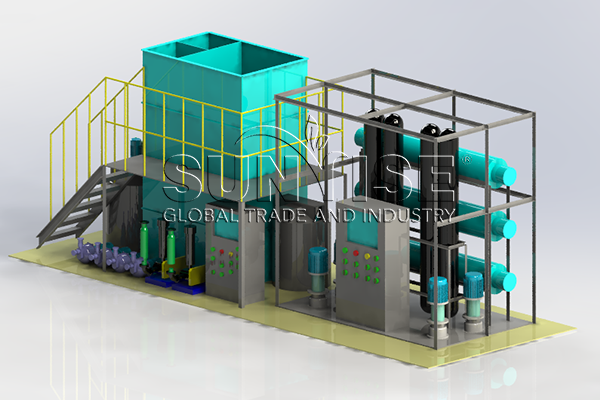

Waste recycling machinery manufacturers play a vital role in the current context of the increasingly serious global e-waste problem. E-waste recycling machinery manufacturers play a key role. Because it not only promotes sustainable development, but also improves e-waste recycling and reduces environmental pollution. Through innovative technologies and equipment, they have injected vitality into the e-waste recycling industry. In addition, they have also contributed to building a resource-saving and environment-friendly society.

Are e-waste recycling machinery manufacturers continuing to invest in research and development to promote the application of new technologies?

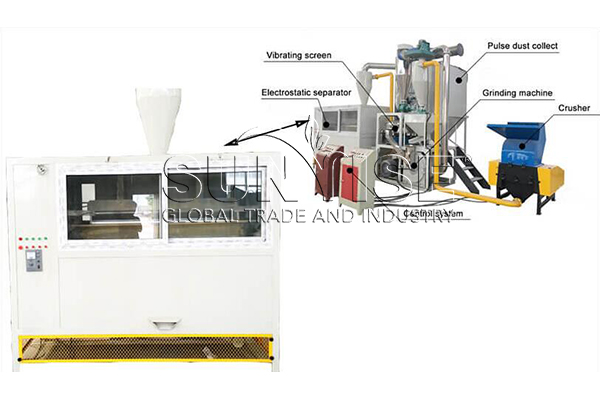

The technology and equipment for e-waste recycling are constantly developing and innovating, which can process and recycle e-waste more effectively and reduce the impact on the environment. Therefore, we have been actively investing in research and development and promoting the application of new technologies to improve recycling efficiency and environmental protection levels. Not only does this help advance our industry as a whole, it also better protects the environment and resources.

4 ways to be environmentally friendly with your equipment from e-waste recycling machinery manufacturers.

Exhaust Emissions

Our equipment is equipped with effective exhaust treatment systems that reduce or eliminate harmful gas emissions. For example, by using filters and adsorbents to capture and treat harmful gases such as VOCs (volatile organic compounds), etc.

Wastewater Treatment

Our recycling facilities have appropriate wastewater treatment systems capable of treating and purifying the wastewater generated. This includes removing heavy metals, organic matter and other harmful substances to ensure that wastewater meets discharge standards and does not pollute the environment.

Energy efficiency

Our equipment design focuses on energy efficiency, minimizing energy consumption by optimizing processes and equipment configurations. Thereby, you can achieve this by using energy-efficient equipment, adopting energy-saving measures, and optimizing work processes.

Hazardous material processing

Our equipment can effectively deal with harmful substances in e-waste. Such as lead, mercury, cadmium and other heavy metals. We therefore need to ensure that they are safely isolated and disposed of to prevent impacts on the environment and human health.

Leave A Comment