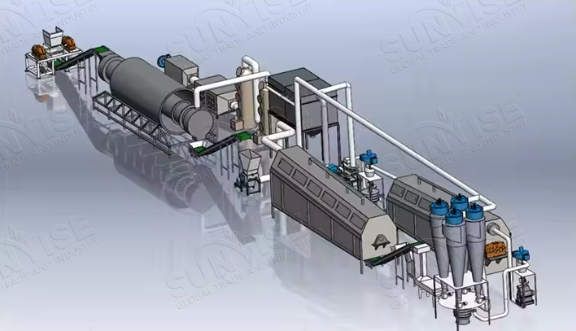

Lithium battery recycling equipment is designed to recover valuable metals and chemicals from waste lithium batteries. Through pretreatment, chemical treatment, purification, and physical treatment, the equipment not only reduces environmental pollution and promotes resource recycling, but also helps to reduce production costs and promote sustainable development. In addition, with the popularization of electric vehicles and portable electronic devices, this technology is particularly critical, effectively recovering metals such as lithium and cobalt, bringing you certain economic benefits. At present, our company’s 1000kg/h lithium battery recycling equipment project has also received widespread attention from customers.

What lithium batteries can be processed by the 1000kg/h lithium battery recycling equipment project?

What is the cost of a 1000kg/h lithium battery recycling equipment project?

At present, this project belongs to small-scale recycling, so its cost is about $12,000. You can choose it with confidence. Of course, if you have other needs, you can contact us. We will give you the most suitable solution for you.

Crushing equipment

In order to achieve small-scale lithium battery recycling, we recommend that you use a double-shaft shredder model YS-300, which can efficiently shred lithium batteries to 2 cm in size, and its structural design optimizes the operating efficiency. The market price of this shredder is about $2,000. In addition, for scenes that require further refinement of the crushing, it is recommended that you use a hammer crusher model YS-200 for secondary crushing. Because the equipment can crush the material to a particle size of about 20 mesh and has the characteristics of a wide range of treatments, it is not only suitable for lithium batteries, but also suitable for processing other types of electronic waste, and the purchase cost is about $3,000.

Screening equipment

In the material sorting stage, in order to improve the recovery rate, you can choose a magnetic separator model YS-200, a specific gravity separator model YS-400, and an airflow separator model YS-300. These devices can effectively separate materials according to their properties (such as magnetism, density, etc.). For example, magnetic separators are specifically used to separate magnetic materials from non-magnetic materials, gravity separators can effectively separate copper and aluminum by comparing the density differences of materials, and airflow separators use the airflow principle to separate materials. The prices of these devices are around $3,000, $2,000, and $4,000 respectively.

Dust removal equipment

In order to ensure environmental standards during the recycling process, it is crucial that you use the activated carbon adsorption equipment model YS-300 for waste gas treatment. The equipment effectively adsorbs pollutants in the waste gas through the large surface porous structure of the activated carbon adsorbent, separates gas from pollutants, and ensures that the purified gas can be discharged safely. The purchase cost of this dust removal equipment is about $1,000.

What can you do with metals and other materials recovered from lithium batteries?

First of all, the specific type of materials and their purity dictate the treatment of metals and other materials recovered from batteries. Generally, after recovery and refinement, manufacturers can reuse these materials in the production of new batteries or other products.

- 1

Direct reuse

Proper cleaning and purification can prepare some materials recovered from batteries, such as certain metals (such as copper, aluminum, etc.), for direct reuse in battery manufacturing or in other industries (such as electronics, construction, etc.).

- 2

Chemical refining

For valuable metals such as lithium, cobalt, and nickel, you usually need to remove impurities and improve the purity of the metal through chemical refining. But this involves a series of complex chemical treatment processes, including dissolution, precipitation, filtration, electrolysis, etc., to finally obtain high-purity metals that can be used to make new lithium batteries.

- 3

Synthesize new materials

- 4

Energy recovery