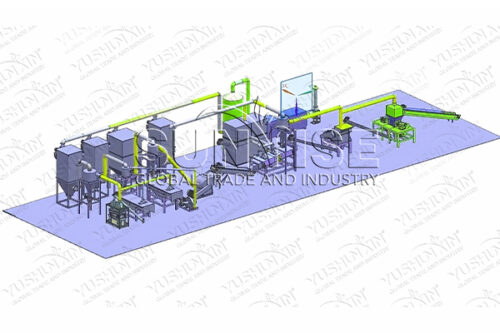

The 1000kg/h solar panel recycling project recovers valuable materials by using solar panel recycling equipment for disassembly, screening, and other steps, and uses technologies such as heat treatment and chemical treatment to maximize the resource recovery rate, which not only greatly reduces the impact on the environment, but also promotes resource conservation and has important economic benefits. In addition, our project further encourages the sustainable development of the solar industry by making new products from recycled materials, which has far-reaching significance for achieving a circular economy and protecting natural resources. Our company specializes in the production of electronic waste recycling equipment and design recycling projects, with an experienced team and trustworthy partners. Our customers express trust and satisfaction with our services and equipment. If you want to know more about electronic waste recycling equipment and recycling processes, please feel free to consult us.

What materials can you recover from the 1000kg/h solar panel recycling project? What applications or industries can these materials be used for?

You can recover a variety of valuable materials from the 1000kg/h solar panel recycling project, which have a wide range of applications and involve multiple industries. Here are some of the main recycled materials and their potential applications.

- 1

Silicon (Si)

Application: Recycled silicon can be purified and reused to produce new solar panels, or used in the semiconductor industry to manufacture electronic components.

- 2

Silver (Ag)

Application: Recycled silver can be used in the electronics industry, such as making conductive pastes, contact materials for electronic devices, etc.

- 3

Copper (Cu)

Application: Recycled copper can be used in wire, cable, electrical appliance manufacturing and other fields.

- 4

Aluminum (Al)

Application: Recycled aluminum can be used again in industries such as building materials, transportation, packaging, etc.

- 5

Glass

Application: Recycled glass can be used to produce new solar panels or reused in the construction and packaging industries.

- 6

Plastics

Application: Recycled plastics can be used as new plastic products or find applications in building materials.

What is the efficiency of our photovoltaic panel recycling project to process 1000kg of solar panels per hour?

Although the efficiency of electronic waste recycling is affected by many factors, our company has specialized in electronic waste recycling projects and designing electronic waste recycling equipment for many years, so we can use advanced technology to a certain extent to stably and efficiently recycle metals (such as silicon, silver, copper, etc.) at around 90%, or even up to 95%. You can fully trust us because we have rich experience and a professional and highly educated team. It is our responsibility to customize the electronic waste recycling process and equipment that suits you.

What innovations are driving solar panel recycling efficiency?

Solar panel recycling is a rapidly evolving field, and innovations are becoming increasingly important as panels reach the end of their lifecycle and demand for sustainability increases. Here are some of our key innovations.

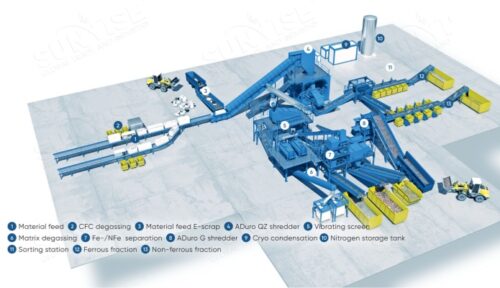

You can separate glass, metals, and other non-metallic materials through mechanical crushing and multi-stage screening. In addition, our approach is being optimized with more precise screening technology and more efficient crushing machinery to reduce the generation of micro-dust and increase the recovery rate of materials.

Since silicon is the main component of solar panels, our R&D staff is exploring efficient ways to recycle and purify silicon. In addition, the encapsulation materials of photovoltaic panels (such as EVA) are usually considered waste. But our technological innovations are exploring how to recycle these materials to increase your recycling profits.

You can use AI to analyze data from recycling facilities, predict equipment failures, optimize recycling processes, and reduce downtime, thereby improving overall efficiency.

How much profit do you make from a 1000kg/h solar panel recycling project?

Because calculating the specific profit of a solar panel recycling project involves multiple variables, including the market value of the recycled materials, recycling processing costs, operating costs, etc. Therefore, the following is a simplified profit calculation model, and the specific situation still needs to be analyzed specifically. In short, the following data is for reference only.

Source of income

Cost input

The gross profit for processing 1,000 kg of solar panels per hour is:

[Gross profit = material sales revenue – (recycling costs + fixed costs + variable costs)] [Gross profit = $500 \times 1 – ($200 \times 1 + $100 + $50 \times 1) = $150]

So, based on these simplified assumptions, a recycling project that processes 1 ton of solar panels per hour may generate a gross profit of about $150.