There is no denying that the e-waste shredder is a device specifically used to deal with electronic waste. Specifically, its main function is to physically crush discarded electronics and break them down into smaller particles or fragments. All in all, e-waste shredders are very important, especially because e-waste contains a lot of valuable metals and other recyclable materials, such as copper, aluminum, steel, etc. In addition, the subsequent sorting and recycling process is simplified by the use of electronic crushers to decompose e-waste. So it helps to reuse resources and reduce waste.

How does an electronic scrap shredder work?

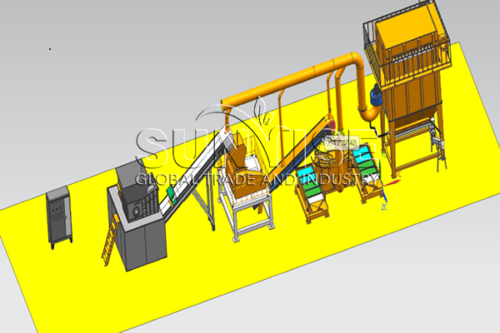

The crusher usually works by mechanical crushing. In summary, the specific work flow is as follows

The first thing to remember is to feed the e-waste to be treated into the crusher through the feed port.

Secondly, mechanical tools such as hammers and blades are used to crush the waste in the primary crushing area. Even so, primary crushing can only break waste into small pieces. Smaller pieces require further crushing.

Following the primary crushing process, the bulk waste must be transferred to the secondary crushing area.And then, finer blades and screens are used to break down the waste into smaller particles.

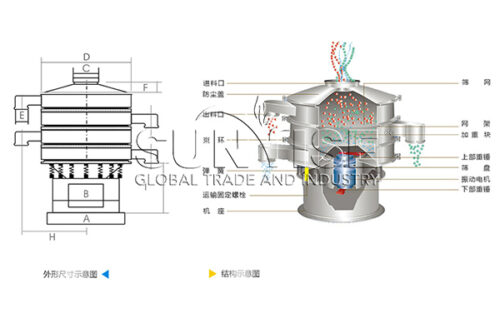

In addition, the screen separates the broken waste particles according to their size, ensuring that all specifications are met. It can be seen that this process is essential to effectively manage e-waste and minimize its impact on the environment.

When appropriate, the crushed waste particles can be further treated according to the specific needs, such as removing impurities through magnetic separation, gravity separation, etc., or subsequent recovery after direct treatment.

What is the important role of using electronic scrap shredders in environmental protection and resource recycling?

The use of e scrap shredders plays the following important roles in environmental protection and resource recycling.

Reduce environmental pollution

As we all know, e-waste is notorious for containing harmful substances like heavy metals, organic solvents, and plastics. Improper disposal can lead to pollution of soil, water, and air. Conversely, the accumulation of electronic waste contributes to environmental pollution. Nevertheless, electronic waste shredders can efficiently handle and decompose waste electronic products. They also help minimize the release of harmful substances, ultimately reducing environmental pollution.

Save resources

The first thing to remember is that you can recycle and reuse valuable materials such as metal, plastic, and glass from e-waste.Therefore, it is essential to use an electronic crusher to crush waste electronic products into small particles. In general, this facilitates the sorting, separation and recovery process, thus ensuring efficient use and recovery of resources.Only in this way can we reduce the need for new raw materials.

2 major advantages of electronic scrap shredders.

This is the advantage of our electronic scrap shredder.

Efficient processing

The efficiency of the electronic shredder is reflected in the following aspects. First of all, it can quickly crush waste electronic products, improve the speed and then efficiency of waste treatment. Secondly, labor and time costs are saved by automating the crushing process. In addition, electronic shredders can effectively disassemble various components of electronic products. To be sure, this increases recycling rates and encourages the reuse of resources. To sum up, electronic shredders are highly efficient.

Reliability

In contrast, our electronic shredder is very reliable. Because they use durable materials and stable performance. In addition, we have implemented sound maintenance measures.These factors combine to guarantee a stable and efficient operation. As a result, we offer a reliable crushing solution.