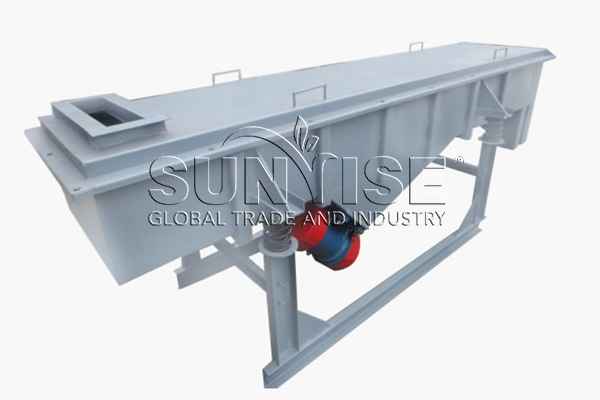

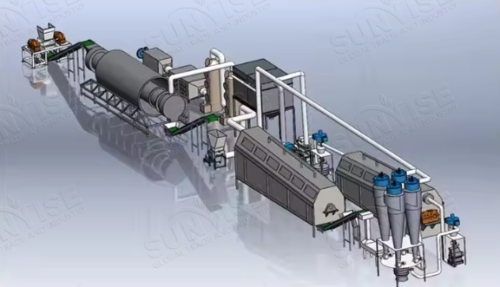

The main function of electronic waste recycling equipment is to participate in the recycling, processing and reuse of electronic waste. Crushing equipment breaks up electronic waste for subsequent processing. Separation equipment separates different materials (such as metals and plastics), and magnetic separation equipment separates iron-containing materials. Electrolysis equipment recycles precious metals, and fine powder processing equipment processes recycled powders. Cleaning equipment cleans recycled materials, pyrolysis equipment decomposes plastics into reusable chemical raw materials, and exhaust treatment equipment treats exhaust gas. The comprehensive application of these equipment realizes the efficient and safe recycling of electronic waste, reduces environmental impact, and increases economic benefits.

What are the electronic waste recycling equipment?

Electronic waste recycling equipment is mainly divided into four categories. I will introduce them to you below.

What factors affect the price of electronic waste recycling equipment?

Equipment scale and production capacity

The price of electronic waste recycling equipment is also related to its scale and production capacity. Larger-scale equipment usually has higher production capacity and can process more electronic waste, so the price is relatively high. For small or medium-sized enterprises, they may only need to process a small amount of electronic waste, so the price may be relatively low for equipment with small scale and limited production capacity.

Material and manufacturing cost

The material and manufacturing cost of electronic waste recycling equipment is also one of the important factors affecting the price. The quality and cost of the materials used in the equipment will directly affect the price of the equipment. The complexity of the manufacturing process, special requirements and technical difficulty will also affect the price of the equipment.

What is the price of the equipment needed to recycle 5000kg of used lithium batteries per hour?

The equipment needed to recycle lithium batteries can be divided into three main categories.

How to compare prices and choose when purchasing electronic waste recycling equipment?

What are the advantages of our company’s electronic waste recycling equipment?

Our e-waste recycling equipment has efficient processing performance and can process a large amount of e-waste in a short time.

Our equipment adopts the latest technology and can effectively separate and recycle valuable materials in e-waste.

In addition, our equipment does not produce harmful substances during the recycling process, meets environmental protection requirements, and does not pollute the environment.

Last but not least, our equipment design takes into account the safety of the operator, the equipment runs stably and reduces the risk of accidents.