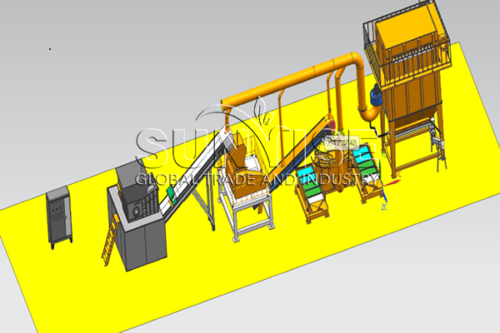

E waste recycling machinery is equipment used to process and recycle discarded electronic products. Its main function is to dismantle, separate, and process waste electronic products, recover valuable metals, plastics, and other materials, while simultaneously disposing of harmful substances and reducing environmental pollution. E waste recycling machinery usually includes multiple functional modules, such as a disassembly module, separation module, crushing module, sorting module, and more. E waste recycling machinery is of great significance in processing discarded electronic products. It can reduce the harm to the environment and human health, protect the environment and ecosystem, and is an important means to promote green development and sustainable development.

What equipment does e-waste recycling machines include?And how do these machines work?

Our e-waste recycling equipment mainly includes the following three categories. We will also introduce to you in detail their working principles. In addition, we will customize the remaining machines according to your specific process flow.

Crushing equipment

The high-speed rotating rotor and hammer are utilized to impact and crush the materials into smaller particles, thereby facilitating the separation and sorting process. This innovative technology ensures efficient and thorough crushing of the electronic waste, enabling the recovery of valuable materials for recycling. In addition, the use of these advanced components in the machinery enhances the overall efficiency and effectiveness of the e-waste recycling process.

Grinder

The material is ground through grinding media to break it into powdery or fine-grained material. Subsequently, the materials that meet the requirements are separated through the screen. This meticulous process helps to ensure that only the desired materials pass through, thereby improving the overall quality and efficiency of the separation process. Additionally, the use of screening technology enhances the precision and accuracy of separating the materials, contributing to the successful recovery and recycling of valuable resources from the e-waste.

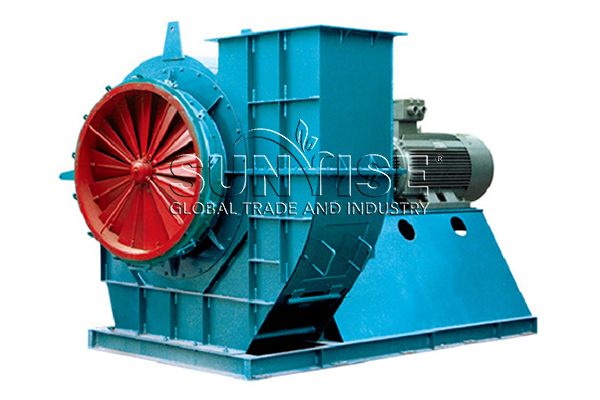

Dust removal equipment

By utilizing the characteristics of activated carbon, this e-waste recycling machinery effectively adsorbs pollutants in the gas onto the surface of the activated carbon. Consequently, this process achieves a purification effect by capturing and removing harmful pollutants from the gas stream. Moreover, by leveraging the adsorption properties of activated carbon, this innovative technology not only contributes to environmental protection but also supports sustainability efforts in waste management.Furthermore, this process not only ensures efficient purification of the gas but also contributes to environmental protection and sustainability efforts.

By combining multiple treatment methods, the removal of pollutants in oil fumes can be achieved effectively. These methods work together to purify the air and eliminate harmful substances.Furthermore, the combination of various treatment techniques enhances the purification process and ensures thorough cleaning of the oil fumes.In addition, by utilizing a combination of treatments, the purification effects are maximized, resulting in cleaner and healthier air quality.

The pores and fiber structure of the filter material are utilized to filter and remove dust from the air effectively. This process involves using the small openings in the filter material to trap and capture dust particles. Additionally, the fiber structure of the filter material helps to physically block and remove larger dust particles from the air. By leveraging both the pores and fiber structure of the filter material, dust can be efficiently filtered and removed from the air, resulting in cleaner and healthier indoor environments.

The e-waste recycling machinery employs the principles of photocatalysis and ozone oxidation. It can utilize these techniques to effectively eliminate harmful substances in the air. Photocatalysis involves using light to activate a catalyst that breaks down pollutants. Ozone oxidation, on the other hand, relies on ozone molecules to oxidize and neutralize harmful substances. By combining these two methods, the e-waste recycling machinery can efficiently remove pollutants and improve air quality.

The nozzle releases the spray, dispersing it over the gas. This causes the pollutants in the gas to come into contact with the liquid. As a result, a chemical reaction occurs, leading to the separation of the gas and liquid. This process effectively removes pollutants from the gas and helps to clean the air.

This e-waste recycling equipment typically features an air inlet that draws in surrounding air. As the air is sucked into the machine, the internal device rotates or swings to accelerate the airflow. Subsequently, the airflow is pushed towards the induced draft fan. An outlet is then created, generating an air current or wind. The exhausted airflow can be transported or distributed through channels such as pipes and air outlets.

Uses the ionization process to ionize oxygen molecules in the air into positively charged oxygen ions. The electric field attracts and attaches the charged particles to the collector, forming a plasma cloud that purifies the particles and organic matter in the air. Contaminants such as chemical compounds and bacteria.

Screening equipment

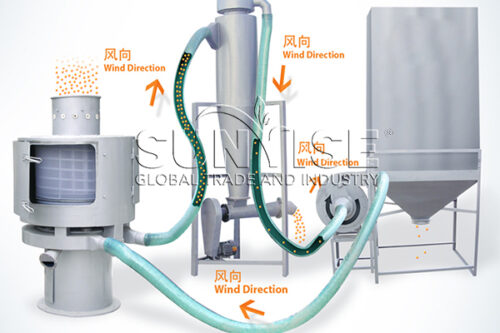

Air flow separator

气流的速度和方向是分拣过程中的重要因素。这些因素在根据物体的密度、形状、大小和其他特征对物体进行分类时起着至关重要的作用。此外,气流有助于有效地分离不同类型的材料并确保准确的分拣结果。此外,通过控制气流,分拣过程变得更加有效,并允许根据特定标准精确分离物体。

Magnetic separator

Linear vibrating screen

By utilizing the vibration of the screen, it is possible to adjust the vibration force and the hole size of the screen to screen the material effectively. This process helps in efficiently separating and sorting materials based on their size and other characteristics.

Specific gravity sorting machine

Based on the different densities of the materials, different floating speeds are generated in the sand discharge tank through the action of gravity to achieve material sorting.

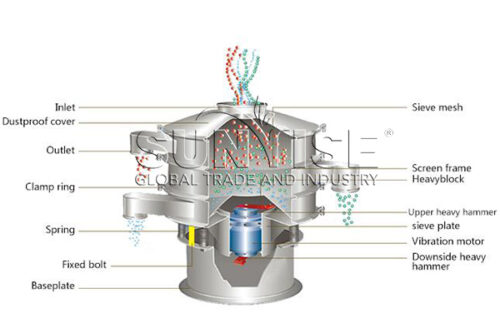

vibro sieve separator

This electronic waste recycling equipment vibrates the materials on the screen surface and actively separates and screens them through the holes of the screen based on the size and shape of the particles. Consequently, smaller particles fall into the discharge port below through the holes, while larger particles remain on the screen surface.

High-voltage electrostatic sorting

The principle of high-voltage electrostatic sorting is to adjust the input power supply and boost it to a high voltage of 100,000 volts through a transformer, forming a high-voltage magnetic field that adsorbs conductive metals, thereby achieving the separation of metals and non-metals.

What is the general process flow of e-waste recycling?

E-waste recycling roughly includes the following processes. However, the specific steps will depend on the type of e-waste you recycle. Our company will provide corresponding e-waste recycling machinery and detailed processes.

Collection and sorting

Firstly, collect the e-waste and then proceed to sort and process it separately according to the different types of electronic devices.Additionally, this systematic approach allows us to properly identify and process each component accordingly. This ultimately leads to a more sustainable and environmentally-friendly disposal of electronic waste.

Hazardous substance treatment

Electronic waste often contains some harmful substances that require special treatment to prevent harm to the environment and human health, such as lead, mercury, and cadmium. Consequently, proper disposal and recycling of e-waste are essential to minimize the negative impacts on our surroundings and well-being.

Why choose our e-waste recycling facility?

Our e-waste recycling equipment has many advantages. I will introduce you in detail below.