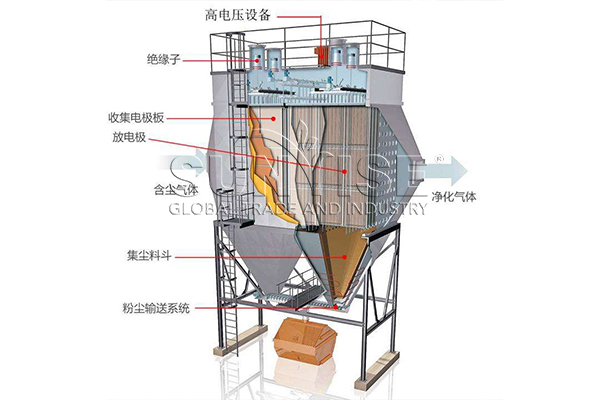

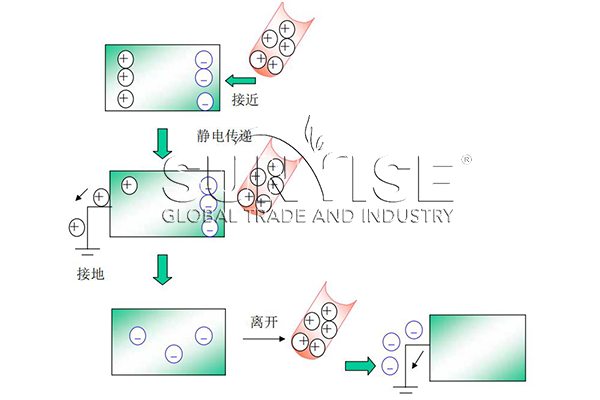

In fact, the role of the electrostatic separator is to separate the particles in the mixture according to their charged properties. Therefore, the purification or classification of particles is realized. There is no doubt that it has important applications in powder treatment, waste treatment, particle separation and other fields. Additionally, electrostatic separators are vital as they can accurately separate particles in a mixture based on their charges. This capability is essential in various industrial processes.Because this is very important for many industries, such as ore separation, powder treatment, waste treatment, etc.

How to use electrostatic separator?

The usage of our electrostatic separation machine is as follows. If you are still unclear, please contact our staff for details.

First, ensure that the power supply and other necessary equipment of the electrostatic separator are connected. In addition, the environment should be clean and dust-free.

Secondly, turn on the power switch of the electrostatic separator. And then wait for the light to come on.Because this indicates that the device is started.

The third is to adjust the parameters as needed. Such as adjusting the separation speed, voltage, etc. In addition, different electrostatic separators may have different parameter adjustment methods.

In addition, it is not only necessary to put the material to be separated into the silo or conveyor belt of the electrostatic separator, but also to ensure that the material is evenly distributed.

Just as important, press the Start button. So the electrostatic separator goes into operation. At the same time, the device uses electrostatic effects to separate materials with different electrostatic charges.

At the same time, observe whether the separated material meets the requirements. And then make adjustments or operations if necessary.

Then when the separation is complete, press the stop button to make the electrostatic separator stop working.

Finally, remember to clean the internal and external equipment of the electrostatic separator in time. To maintain the normal operation of the equipment.

6 advantages of electrostatic separators.

Our electrostatic separation machine has many advantages. Let me summarize a few of them.

Efficient separation

First of all, our electrostatic separator can effectively separate materials with different electrostatic charges. Therefore, the separation efficiency and accuracy can be improved.

Versatility

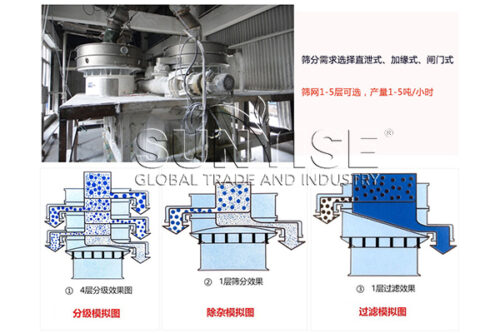

Secondly, the electrostatic separator is suitable for a variety of materials. Such as plastic particles, metal powder, paper and so on. So it has a wide range of applications.

No additional media required

The third is that our electrostatic separators do not require the use of chemicals or other media in the separation process. Therefore, the pollution to the environment is reduced.

Automated operation

In addition, our electrostatic separators can be automated. That’s how it works so it reduces manual intervention and increases productivity.

In addition to the above 2 advantages, there are also the following three advantages. So we are worthy of your trust and choice.

Energy saving and environmental protection

As we all know, our electrostatic separators usually employ advanced electronic control systems and energy efficient designs. As a result, energy consumption and operating costs are reduced.

Strong adaptability

In addition, our electrostatic separators can adjust the parameters according to the characteristics of different materials. Because of its strong adaptability, it can meet different separation requirements.