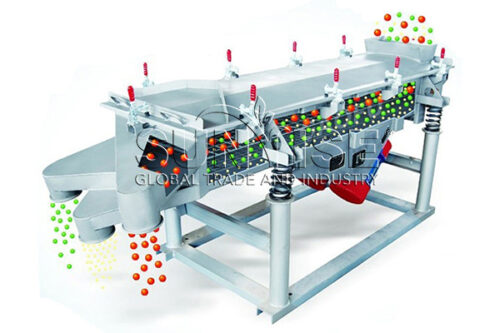

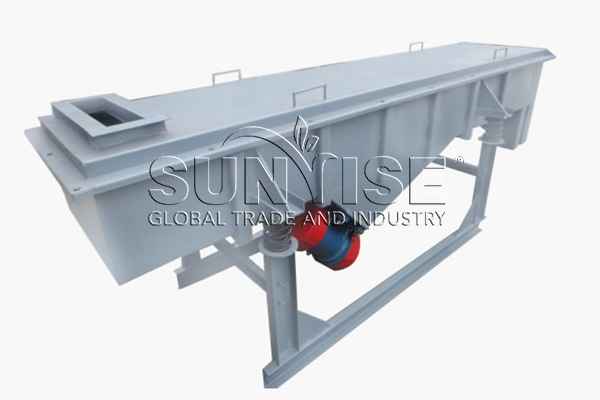

Linear vibrating screens are a common type of screening equipment, screens, and filter materials with a linear motion trajectory. It is widely applied in industries such as mining, coal, metallurgy, building materials, refractory materials, and more. Linear vibrating screens have been applied in many industries, playing a key role in improving production efficiency and reducing production costs. They also protect the environment, demonstrating great work value.

What are the advantages of our Linear vibrating screen?

In what electronic waste recycling processes can linear screens be used?

The linear vibrating screen is a prevalent type of screening equipment. It screens and filters materials using a linear motion trajectory. Furthermore, it’s extensively utilized in several industries such as mining, coal, metallurgy, building materials, refractory materials, and others. Linear vibrating screens play a pivotal role in enhancing production efficiency and reducing costs, proving their significant work value. Furthermore, they contribute significantly to environmental protection, offering great advantages across various industries.

What is the price of linear vibrating screen?

First and foremost, several factors directly impact the price of a linear vibrating screen. One of the primary factors to consider is the equipment’s specification and model. In addition, different specifications and models of linear vibrating screens offer varying screening capabilities and processing abilities. As a result, the price of each model will differ significantly. For example, the model YS-500 linear screen costs about $3,000, but the model YS-800 vibrating screen costs about $5,000. Generally speaking, the price of linear vibrating screens with larger specifications and higher processing capacity will be relatively high.

Secondly, the price of the linear vibrating screen is also related to the brand and quality of the equipment. Well-known brands of linear vibrating screens typically boast strong technical research and development capabilities. Additionally, the market responses have confirmed the quality assurance these brands offer. Consequently, the price of these branded linear vibrating screens tends to be relatively high. For example, Siemens, Schneider, and other large brands have relatively high prices, and some small manufacturers or low-quality products have relatively low prices, but there may be certain risks in service life and stability. The specific price of the straight screen to buy or according to your specific needs.

What is the difference between linear vibrating screen and circular vibrating screen?

Processing capacity

The circular vibrating screen promotes the rapid distribution of material. Because it features an upper end of the elliptical long axis and a discharge end in the opposite direction. In addition, this design reduces the movement speed of the material. The main shaft of the circular vibrating screen can be inverted, enhancing the screening efficiency. So, this feature is particularly beneficial for screening difficult materials. Furthermore, the circular shape of the screen surface enlarges the effective area, thus improving the processing capacity.

Scope of application

A circular vibrating screen actively screens large particles, materials of high hardness, and those with a large ratio. Therefore, it is frequently utilized in industries such as quarrying, mining, and coal; In addition, the linear vibrating screen is ideal for screening fine particles and materials that are not highly hard or lightweight. Typically, these materials include powders. On the other hand, it is widely used across various industries like building materials, chemicals, food, and medicine due to its efficiency and versatility.