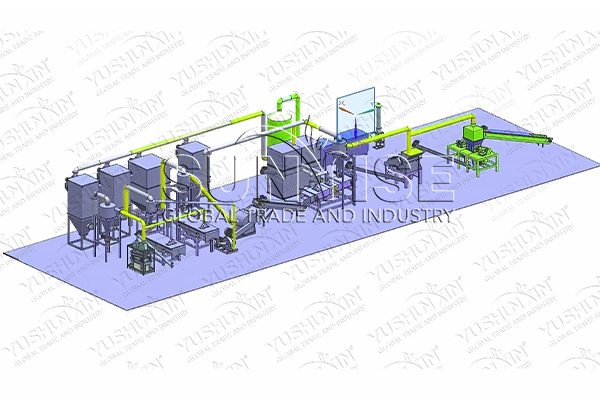

First of all, lithium battery recycling equipment is an e-waste recycling machine and it actively processes and recycles waste lithium batteries. Such as crushers, linear screens and other equipment. In addition, with the widespread application of lithium batteries and the increase in production scale, the recycling and processing of used lithium batteries has become an urgent environmental problem that needs to be solved. Lithium battery recycling equipment actively breaks down analysis and technology through a series of processes. Not only can valuable substances be extracted from used lithium batteries to achieve resource recovery, but it can also prevent environmental pollution and resource waste.

How do you use our lithium battery recycling equipment for recycling?

Then there is how the four recycling processes of our lithium battery recycling equipment work.

How does our lithium battery recycling equipment perform recycling work?

Lithium battery recycling equipment works as follows.

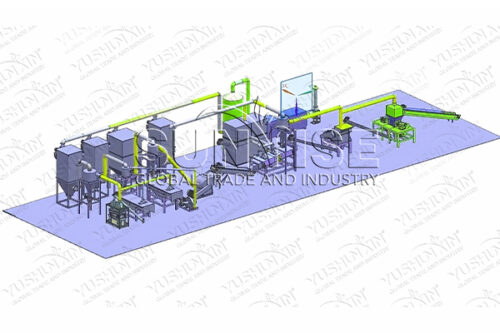

This lithium battery recycling equipment mainly crushes used lithium batteries, and then separates and discharges the crushed materials through a screen or discharge port.

Hammer crusher

The work is done by utilizing high-speed rotating rotors and hammers. Therefore, the material can be broken into smaller particles by impact. This lithium battery recycling device further crushes materials.

Not only the speed but also the direction of the airflow can be used to classify objects based on density, shape, size and other characteristics. Separate plastic septum.

By adjusting the magnetic field and magnetic separator, different magnetic substances can be sorted, thus it can purify ores or recover useful minerals. Separate iron.

The material is sheared and torn by high-speed rotating blades thus it can be extruded into smaller particles or filaments. This is a third-level crushing, which can finally be crushed to about 20 mesh.

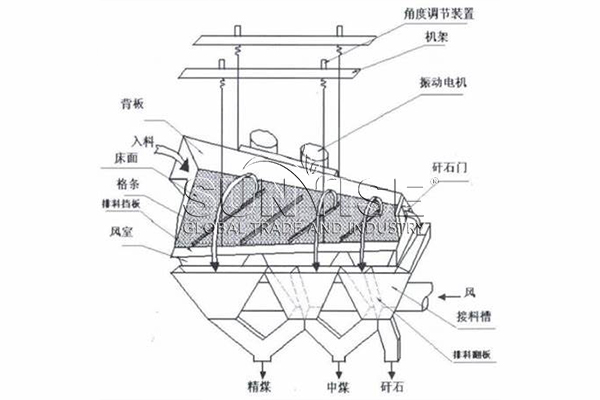

Linear shaker for lithium battery recovery equipment.

The vibration of the screen is used and the material is screened by adjusting the vibration force and the hole size of the screen.Screen out black powder produced during lithium battery recycling.

Grinder for lithium battery recycling equipment.

The material is ground through grinding media to break it into powdery or fine-grained material. Additionally, the sieve separates the materials that meet the requirements. Grinding copper, aluminum.

In addition, the specific gravity separates the resin powder from the copper. Since copper is heavier than resin, it is possible to separate them. It is certain that this is the most advanced technology in the country, which can achieve more than 99% of the metal sorting effect.

Consolidate, store and transport bulk materials, thus improving material management efficiency and operational efficiency.

This equipment can not only perform low-temperature processing of items by controlling the heating system and temperature control system, but our company has equipped it with heat insulation and cooling systems that can also perform low-temperature processing of items.

How can you use our lithium battery recycling equipment in an environmentally friendly way?

These lithium battery recycling equipment of ours can not only help you solve this problem, but also improve production efficiency and reduce production costs by reducing the impact of dust and particulate matter on production equipment and the working environment.

What methods can you use about lithium battery recycling?

Which lithium batteries are worth recycling with your lithium battery recycling equipment? What are they recycled from?

What precautions do you take when recycling lithium-ion batteries?

If you need to recycle lithium batteries, then you need to make sure your operation is safe.

When recycling lithium-ion batteries, you not only need to wear personal protective equipment and use specialized equipment and tools, but also avoid damaging the batteries and store them properly in a fire-proof and well-ventilated place. In addition, strict compliance with regulatory standards is also required to ensure safe operations. and important steps in environmentally friendly treatment.