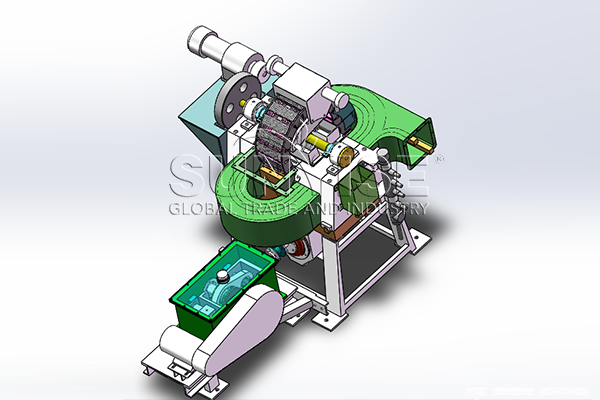

Magnetic sorting machine is a device that uses magnetic force to separate and classify materials. Thus, it can help achieve efficient sorting of magnetic materials, reduce impurities, improve product quality and recycling rate. More importantly, magnetic sorting machine has significant application value in various fields such as mining, metallurgy, and building materials. In addition, you also widely use it in the chemical industry and environmental protection sectors. By doing, it can separate valuable magnetic ores from ores, improving the utilization rate. Furthermore, in waste treatment, this equipment separates useful recycling substances, reducing resource waste and environmental pollution. Besides, in the production process, the machine achieves product refinement and classification. This also helps improve product quality and market competitiveness.

What types of materials can a magnetic separator separate and classify?

You can separate and sort many different types of materials with magnetic separators, including but not limited to the following.

Although the magnetic properties of the material can determine the scope of application of the magnetic separator. But factors such as particle size, shape and composition also play an important role in its effectiveness. Therefore, when dealing with different materials, different magnetic separator models and parameter settings may be required. So if you are considering buying a magnetic sorter, please feel free to contact us. We will advise you on the specific materials you use.

How to operate the magnetic separator?

The operating process of the magnetic sorting machine is as follows.

Operators should be familiar with the working principle, structure and operating procedures of the magnetic separator, and abide by relevant safety regulations and operating procedures.

Before operation, you should first check whether the electrical connection of the equipment is normal, whether the magnetic system is normal, whether there is abnormal noise, etc.

During operation, appropriate adjustments and settings should be made according to the characteristics and requirements of the materials being processed to ensure the sorting effect.

It is strictly prohibited to bring non-magnetic substances or easily magnetized substances close to the magnetic separator to avoid damage and malfunction of the equipment.

After the operation, the power should be turned off in time, and the equipment should be cleaned and maintained.