Mobile phone battery recycling generally involves the collection, classification, and testing of valuable materials.This process involves treating materials physically or chemically, reusing or selling them, and treating waste.Recycling these materials not only reduces the mining of mineral resources and environmental load, but also promotes resource utilization, contributing to sustainable development. Furthermore, it helps prevent harmful substances from entering the environment, safeguarding ecosystems and human health.

What equipment are used in our mobile battery recycling process and what is their workflow?

Mobile battery recycling involves a lot of equipment. The following are the specific processes we have set up and the equipment used.

Shredder

This mobile phone battery recycling equipment mainly crushes used mobile phone batteries, and then separates and discharges the crushed materials through a screen or discharge port.

Hammer Crusher

The high-speed rotating rotor and hammer are used to impact and crush the materials into smaller particles. This mobile battery recycling device further shreds the material.

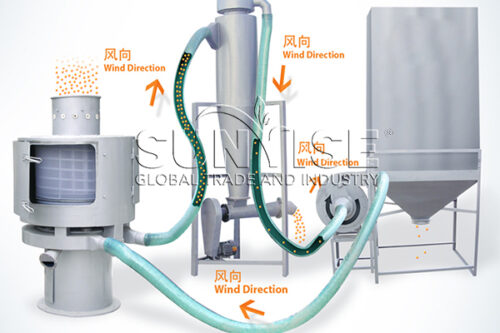

Air flow separator

Operators use not only the speed but also the direction of the airflow to sort objects based on density, shape, size and other characteristics. Separate plastic septum.

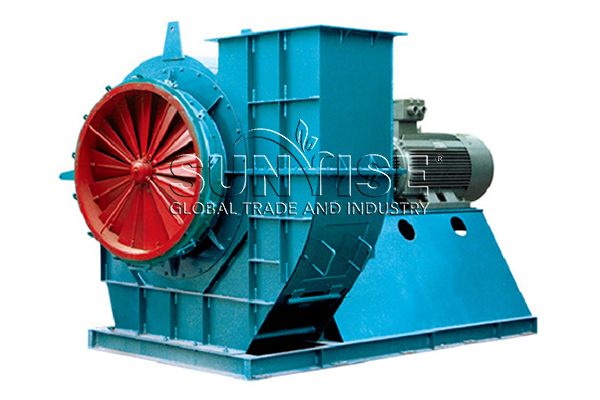

Diaphragm fan

The negative pressure of the inlet extracts the diaphragm fragments on the air flow separator screen.Then, the diaphragm fan actively discharges the diaphragm fragments to the diaphragm box of the next process.A diaphragm negative pressure conveying power device facilitates this process.

Diaphragm box

First of all, the diaphragm scraps enter the diaphragm box through the induced draft fan. next the upper part of the diaphragm box is equipped with an air inlet, which is connected to the rear-end pulse dust collector. In addition, there is a screen inside. Subsequently, the dust in the diaphragm scraps in the diaphragm box is sent through the screen. Afterwards, the end pulse dust collector collects and discharges, and the diaphragm scraps are isolated by the screen and fall into the lower part of the diaphragm box.Finally, the hinge conveyor device equipped in the lower part of the diaphragm box sends out the diaphragm scraps inside the diaphragm box for collection through the hinge leaves.

Pulse dust collector

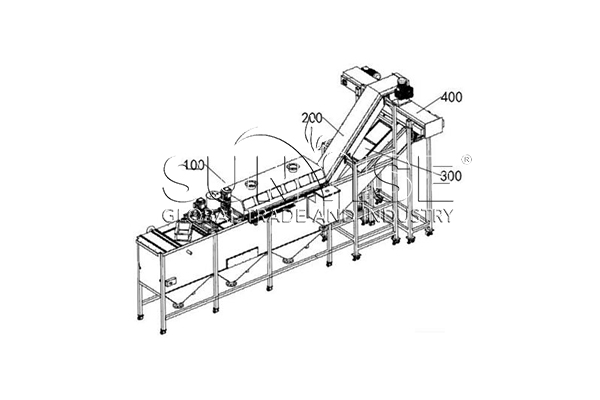

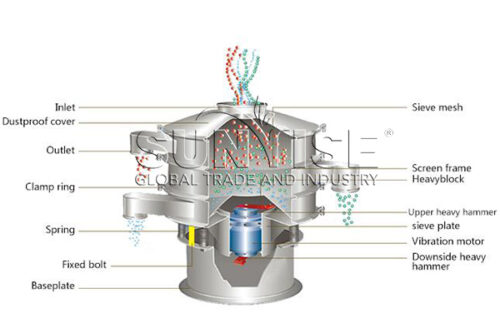

Linear vibrating screen

Adjusting the vibration force and the hole size of the screen uses the vibration of the screen to screen the materials.Screen out the black powder produced during the recycling process of mobile phone batteries.

Grinder

The material is ground through grinding media to break it into powdery or fine-grained material. Additionally, the sieve separates the materials that meet the requirements. Grinding copper, aluminum.

Specific gravity sorting machine

According to the different density of the materials, different floating speeds are generated in the sand discharge tank through the action of gravity to realize material sorting. Sorting copper and aluminum.

Collectors

Consolidate, store and transport bulk materials, thus improving material management efficiency and operational efficiency.

Low temperature furnace

This equipment can not only perform low-temperature processing of items by controlling the heating system and temperature control system, but our company has equipped it with heat insulation and cooling systems that can also perform low-temperature processing of items.

Spray tower

The gas enters the tower from the lower inlet of the tower and moves upward. After passing through the filler, the exhaust gas fully contacts the liquid phase and is absorbed, and then enters the next process through the upper dehydration layer to achieve the purpose of dust removal; the filtration air volume of the spray tower is 30000m³/h, and the purification efficiency ≥99%;

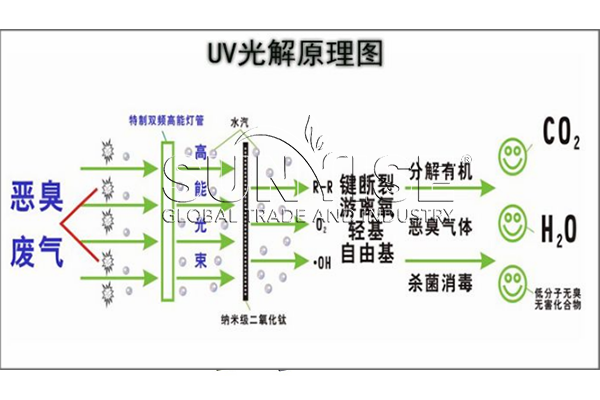

2 major environmental protection treatment equipment and processes.

Activated carbon adsorption box

The gas passes through the spray tower and enters the activated carbon adsorption box. Subsequently, the activated carbon adsorbent surface utilizes its adsorption capacity to adsorb the pollutants in the exhaust gas, effectively separating them from the gas mixture. Additionally, the activated carbon adsorption box is of the dry type. Furthermore, the exhaust gas treatment equipment comprises a box and an adsorption unit filled in the box. Notably, the filtered air volume of the activated carbon adsorption box is 30,000m³/h.

What are the advantages of different crushing equipment in our mobile phone battery recycling?

Our company has obtained national utility model patents and invention patents for the mobile phone battery crushing and recycling equipment we have produced. In comparison to similar domestic technical processes and production equipment, the mobile phone battery crushing equipment produced by our company has the following advantages. Moreover, it outperforms the equipment of existing domestic enterprises.

Hammer crusher

The hammer crusher adopts the form of hook knife + hammer head. The high-speed and high-torque motor drives the hammer head on the main rotor to take turns hitting the battery scraps in the cavity through the space formed between the lining plate and the hammer head. As a result, the battery scraps can be fully and effectively crushed in the crushing cavity. Furthermore, the hook knife on the main machine rotor fully breaks up the separator in the battery scraps through rapid rotation. At the bottom, there is a screen that meets the requirements for particulate matter. Additionally, it helps to ensure cleaner production. Finally, the materials enter the conveying device through the screen and enter the next process to facilitate subsequent processing.

Pulverizer

This crusher adopts a blade crusher, which uses the rapid impact of the blades. Therefore, mobile phone batteries can complete fine crushing. Because the equipment has high crushing efficiency and low resistance, it is suitable for crushing soft and hard materials. In addition, it has a screen at the bottom. Therefore, the material is transferred to the next section through the screen under the action of wind in the processing process. The material that meets the crushing requirements.Moreover, the whole production process has low noise and low energy consumption.The crushing equipment sends the dust generated during the most important crushing process to the aggregate facility and dust collection facility through the closed negative pressure system, meeting the requirements of cleaner production.

Grinder

Use a cutterhead grinder. By adjusting the gap between the cutterheads, not only can various materials be flexibly processed to ensure sufficient grinding of the materials, but also the lithium battery materials (positive and negative electrode powder) can be separated from the metal to the greatest extent. This process ensures the purity and recovery of the finished product.

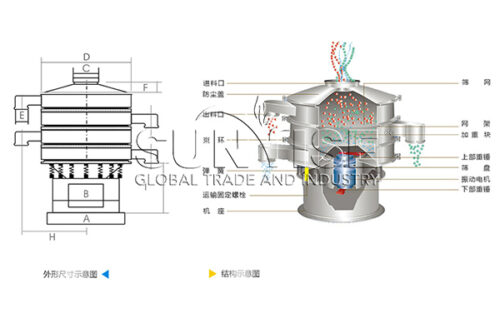

Diaphragm sorting system

Our company designed and manufactured the sorting mechanism specifically for mobile phone battery separators among the mobile phone battery crushing and sorting equipment. Moreover, Our company exclusively invented this special sorting equipment. In addition, it is a complete set of equipment consisting of air flow separator + diaphragm fan + diaphragm box + pulse dust collector. Finally, it mainly collects and discharges the separator fragments in mobile phone batteries through the process of vibration screening + air flow sorting.

Specific gravity sorting machine

The specific gravity separator is a special equipment for sorting and processing lithium mobile phone batteries.It mainly separates material particles based on their different specific gravity.In addition,in mobile phone battery processing projects, we mainly use it for sorting metals (copper and aluminum). It is a special, high-precision screening product.

If you want to purchase this equipment or have any questions, please feel free to consult us. Our professional team will be happy to provide you with detailed product information and answer your questions.