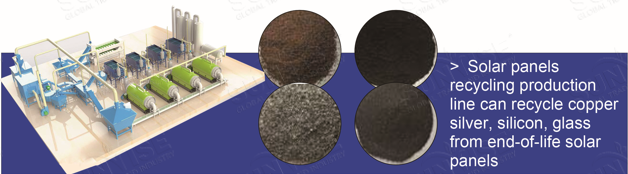

Old solar panel recycling equipment is a kind of equipment specially used for processing discarded solar panels. Due to the large number of old solar panels, we found the economic benefits and began to produce recycling equipment. The emergence of solar panel recycling equipment provides an efficient, environmentally friendly, and economical solution to this problem. Therefore, it promotes environmental protection and sustainable use of resources. However, the price of old solar panel recycling equipment is affected by many factors, including equipment brand, processing capacity, and technical complexity. If you have specific needs, please feel free to consult us. We will give you detailed equipment information and the price of old solar panel recycling equipment.

How much does old solar panel equipment cost?

The price of old solar panel recycling equipment is affected by many factors. Below I will distinguish the price difference based on the processing capacity.

Which equipment can ensure that the recycling process is more environmentally friendly?

Although our old solar panel recycling equipment is environmentally friendly, some equipment is still needed to purify the exhaust gas or wastewater during recycling.

Pulse dust collector

You can use our pulse dust collector to remove exhaust gas with confidence. First, it uses efficient pulse dust removal technology to improve the filtration efficiency to about 99%. Secondly, the equipment has a compact structure and occupies a small area, which is easy to install and maintain. Therefore, you can reduce costs. Thirdly, the use of high-quality filter materials is durable and prolongs the service life of the equipment. It also reduces costs fundamentally. Finally, it is simple to operate and has a high degree of automation, which reduces manual intervention and reduces operating costs. The device costs between $5,000 and $7,000.

Our activated carbon adsorption equipment has the advantages of high adsorption efficiency and strong capacity. It can treat multiple mixed organic waste gases at the same time, and the purification efficiency is ≥95%. In addition, the equipment has a compact structure, small footprint, simple maintenance and management, and low operating costs. Finally, it adopts an automated control design, which is easy and safe to operate. The fully enclosed design is suitable for indoor and outdoor environments. The price of this equipment is between $4,000 and $8,000.

Is recycling old or broken solar panels a profitable industry?

Recycling old or damaged solar panels is economically profitable. Because solar panels contain many recyclable resources. I will introduce them to you below. In addition, if you use our electronic waste recycling equipment, you can increase the recycling rate and increase your profits.

What other equipment can improve recycling rates in solar panel recycling?

A pyrolysis device can help improve your recovery because you can use it to dissolve the EVA.Below I will introduce to you the advantages of our pyrolysis equipment.The equipment costs between $50,000 and $100,000.