With the rapid development of society, the disposal and recycling of waste photovoltaic panels, waste tires and other waste has become an important environmental problem. But the pyrolysis machine can effectively solve this problem. Specifically, people use pyrolysis devices to decompose waste photovoltaic panels and so on. Therefore, its main function is to break down waste. Thus recovering valuable substances. At the same time, the recovery rate of resources can be improved. To sum up, it can not only reduce environmental pollution, but also improve the efficiency of resource utilization.

What specific machines does pyrolysis machine include and What materials are processed?

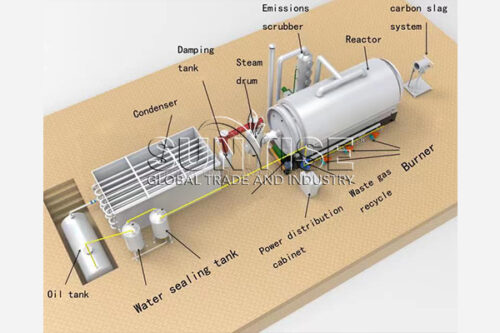

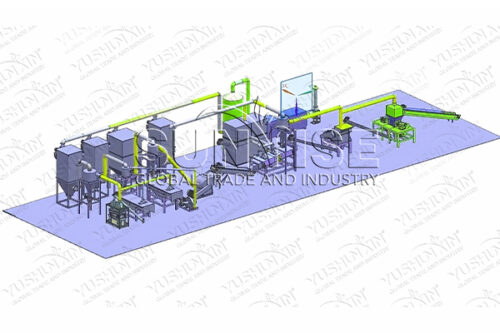

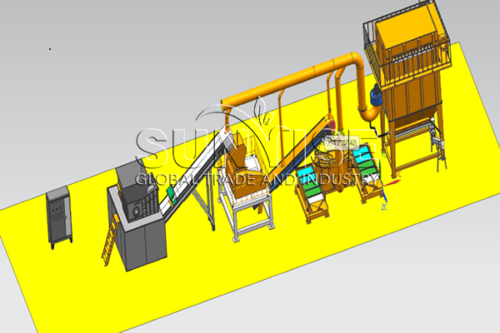

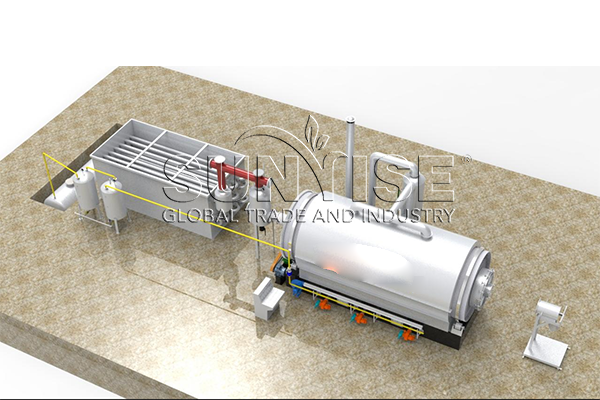

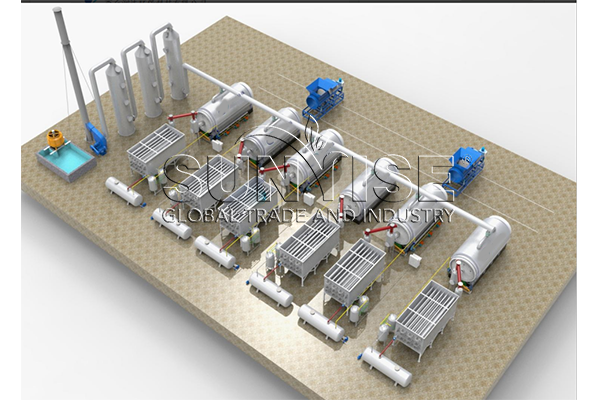

The pyrolyzer includes a hydraulic feeder and a cracking furnace. Also included are buffer tanks, fuel tanks, three-stage condensing systems, safety devices and environmental protection devices.

In addition, the materials that can be processed by the pyrolysis machine are not only circuit boards and photovoltaic panels. In addition, there are waste rubber, waste tires and waste batteries.

How does our pyrolysis machine work?

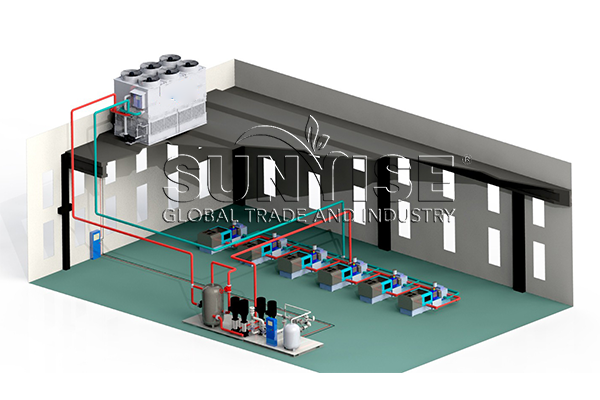

The two major equipments, cooling water tank and pyrolysis furnace, are important cracking equipment of our company. Now let me introduce to you how they work.

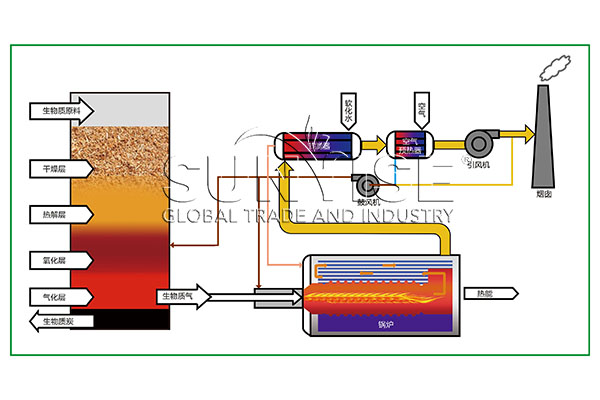

Cooling water tank

The circulating water mercury sucks the cold water stored in the water tank into the circulation system. After passing through the equipment parts to be cooled, it exerts a cooling effect and then flows out with higher temperature water. After the water circulation radiator and cooling fan actively cool it, the water rejoins the new cycle.

Cracking furnace

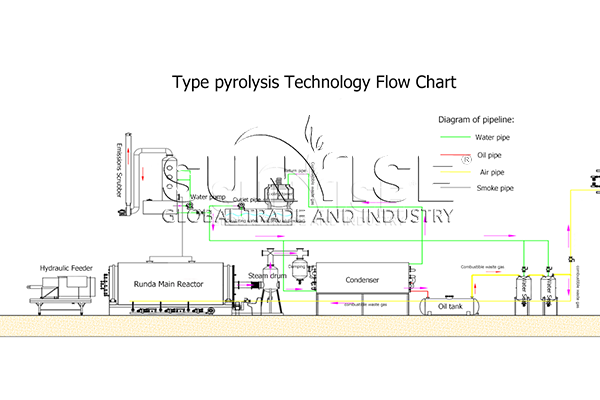

The working principle of this pyrolysis machine is that the waste material enters the furnace. When the temperature rises to about 120 degrees, cracking begins, which takes about 8-10 hours.Generally, heating for 2 hours will produce cracked oil and gas.The oil vapor is condensed into liquid oil through the cooling system. In addition, the material will also produce some flammable but non-condensing gas during the process of heating and cracking. So we call it “tail gas”. Recycling this gas can directly use it in the heated cracking reactor to save fuel use. Finally, when you complete the cracking process, the refinery will discharges the oil and gas. If you need to discharge the residual material in the reactor, you need to implement a new cracking process. These residual materials are mainly carbon black.

What is the process of cracking process?

The pyrolysis process is as follows.

Why choose our pyrolysis machine?

Our pyrolysis machine has these five major advantages, making it safer and more secure for you to choose us.

Direct heating

By conducting theoretical calculations and analyzing actual data, we can design it reasonably. At the same time, we greatly increase the heating area of the furnace body, effectively extending the service life of the equipment.

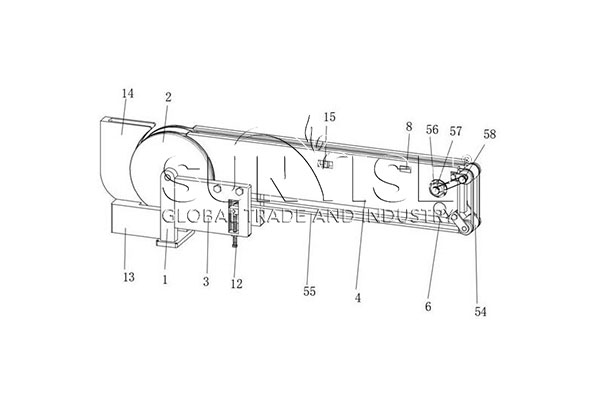

Eight-shaped tug support

Another point is that this set of equipment uses a new figure-eight trailer. Therefore, the furnace body can effectively decompose the stress point supporting it, so that the cracking equipment can run more smoothly.

High-temperature spiral slagging system

Next, if the cracking is completed, then at the same time, the temperature will be controlled at about 200-220 ° C. At this time, the primary slagging system and secondary slagging system can be opened. Because the carbon black needs to be cleaned. To sum up, its features: high temperature resistance, airtight, automatic slag discharge, clean and dust-free.

Spray coil cooling system

Finally, utility model technology that uses air, spray water, and cooling towers to circulate and cool condensable oil and gas.

What after-sales services are available for using our cracking equipment?

If you use our pyrolysis machine, then you can get these services.

Technical support

First, provide technical support services such as equipment operation guidance and maintenance methods. Therefore, it can help customers solve the problems encountered in the use of equipment.

Maintenance services

In addition, we can provide regular maintenance and repair services for the equipment. Therefore, it can ensure the normal operation of the equipment and extend the service life of the equipment.

Parts supply

In third place, we provide spare parts for replacement or repair. Because it ensures that you can repair the device promptly when a problem arises, extend the service life of the device and improve the user experience.

Training services

Finally, we provide customers with equipment operation and maintenance training to help them better use and maintain equipment. Thus, this can help reduce the occurrence of equipment failure and damage.