Small-scale copper recycling plants play a vital role in significantly reducing the demand for copper resources and environmental pollution by collecting and processing scrap copper materials. These manufacturers not only contribute to environmental protection by saving energy, reducing emissions and reducing waste landfills, but also promote resource recycling and contribute to the circular economy model. In addition, they provide economic opportunities for small-scale businesses, create jobs, and demonstrate the value of recycled copper in reducing costs and driving economic development. With the increasing awareness of environmental protection and resource recycling, the role of these manufacturers has become increasingly prominent and has become an indispensable part.

How do you recover copper from e-waste?

Recovering copper from e-waste is a specialized and technology-intensive process that involves physical and chemical methods to extract copper from used electronic products. Here is the basic process we recommend for you to recover copper from e-waste.

First, you need to collect used electronic products such as broken computers, mobile phones, TVs, printers, etc. In addition, pre-processing includes removing the housing, batteries and other parts of electronic products that may contain hazardous substances, and manually or mechanically separating copper wires and other easily recyclable parts.

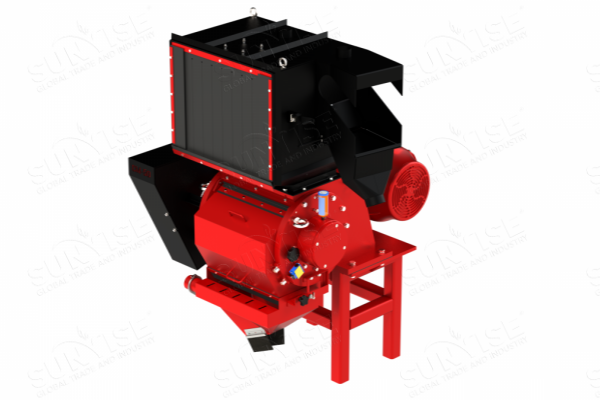

Next, you need to crush the e-waste into small fragments for further processing. You can use our professional crushing machinery for this step. After crushing, copper and other metals are separated from non-metallic materials (such as plastics and glass) by air separation, magnetic separation, gravity separation, or flotation. Our company has professional equipment for all of these.

How can a small copper recycling plant ensure the environmental friendliness of the recycling process?

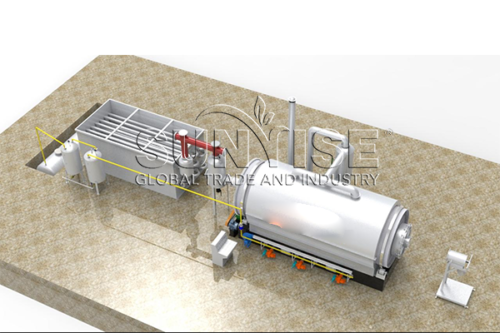

In addition to using the equipment mentioned in the above question to reduce environmental pollution, you can also use the following equipment for professional exhaust gas and wastewater removal.

What are the biggest challenges facing small copper recycling plants? How to solve this problem?

If you want to set up a small copper recycling plant, one of the biggest challenges you will face is cost control and the instability of raw material supply. Due to your small size, it is difficult for you to obtain a stable and reasonably priced supply of electronic waste raw materials. At the same time, compared with large recycling companies, you are also at a disadvantage in terms of raw material procurement, technology investment, production efficiency, and environmental protection measures. These factors together lead to huge pressure on cost control.