PCB recycling involves extracting printed circuit boards from scrap electronic devices and recovering the precious metals and materials contained therein, such as gold, silver, copper, etc. This process involves collecting scrap electronic products, disassembling, separating PCBs, and recovering precious metals using chemical or physical methods. Small-scale PCB recycling plants are dedicated to recovering precious metals and other valuable materials from scrap electronic devices to support the circular economy and gain economic benefits from them. You can use our electronic waste recycling equipment to process PCB in a small-scale PCB recycling plant through the methods I mentioned above, which can not only increase the recycling rate but also generate more economic benefits.

What electronic waste recycling equipment will small-scale PCB recycling plants use?

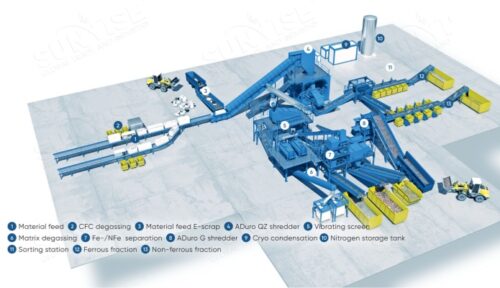

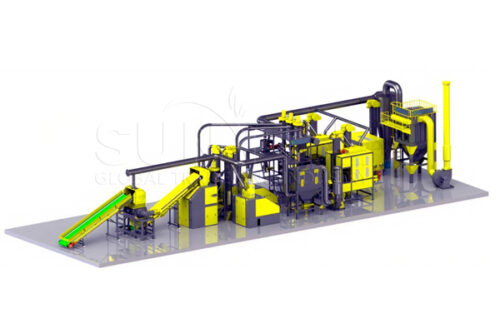

When a small-scale PCB (printed circuit board) recycling plant processes electronic waste, especially when recovering and extracting metals from PCB, you may use a range of specialized equipment and tools. The following are some common electronic waste recycling equipment.

How can a small-scale PCB recycling plant ensure the purity and quality of metals extracted during the recycling process?

Suppose you want to set up a small-scale PCB (printed circuit board) recycling plant and want to ensure the purity and quality of metals extracted during the recycling process. In that case, the following measures are usually adopted.

What is the cost of setting up a small-scale recycling plant?

If you want to set up a small-scale recycling plant and follow our solution process, it will only cost about $22,000.

Why choose to buy our company’s e-waste recycling equipment?

The choice of buying our company’s e-waste recycling equipment is based on multiple favorable factors and features.

- 1

Advanced technology

We achieve high efficiency in e-waste recycling by adopting the latest technology to improve recycling efficiency and material recovery rate, while applying environmentally friendly technology to reduce the emission of harmful substances and meet international environmental standards.

- 2

Cost-effectiveness

We reduce operating costs and increase productivity by adopting equipment with high operating efficiency. Although facing a higher initial investment, in the long run, you can achieve a better return on investment by improving recycling efficiency and reducing operation and maintenance costs.

- 3

Customized solutions

We will provide customized solutions according to your specific needs, and provide one-stop services from planning and design to installation and commissioning to after-sales service to ensure that you can run smoothly and maximize its benefits.

- 4

Industry experience and reputation

Our company has rich experience in the field of e-waste recycling, has successful cases and a good market reputation, which can be an important factor in your trust choice.