A cable recycling production line, a comprehensive processing and recycling system designed for waste cables, aims to extract valuable metals such as copper, aluminum, and plastic from discarded cables to achieve resource reuse. This process of our company covers key steps such as pretreatment, stripping, crushing, sorting, cleaning, and drying to smelting and granulation, which not only significantly reduces the need for new raw materials, but also significantly reduces environmental pollution. In addition, if you are interested in cable recycling production lines, please feel free to consult us. Our company has specialized in e-waste recycling for about 8 years and can meet your recycling needs in all aspects.

How does a cable recycling line work?

The recycling line of the cable mainly processes and recycles waste cables through physical methods. Its basic working principle and process can be summarized as the following steps.

- 1

Pretreatment

This step includes sorting, shearing and crushing the waste cables, cutting them into smaller pieces or strips to facilitate subsequent separation. In short, the purpose of pretreatment is to reduce the size of the material and improve the separation efficiency.

- 2

Crushing

You can further crush the pretreated cables into smaller particles through a dedicated crusher to facilitate the separation of metals and insulating materials (such as plastics or rubber). This step is the key to achieving effective material separation.

- 3

Separation

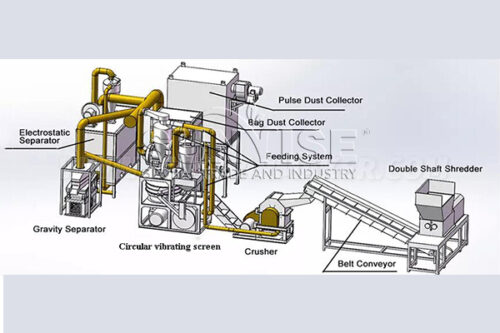

Most importantly, you need to separate the crushed materials through separation equipment. Common separation methods in our company include airflow separation, gravity separation, electromagnetic separation, etc. These separation technologies can effectively separate metal and non-metallic materials. In addition, metal particles can be collected by gravity sorters or other separation equipment due to their heavy weight, while lightweight non-metallic materials such as plastics are carried away by airflow or separated by other means.

- 4

Purification

Finally, the separated metal particles may still contain some impurities and need to be further purified to improve the purity of the metal. This may include secondary crushing, screening, washing, and other steps.

How do you ensure effective separation of metals and plastics during cable recycling?

Ensuring effective separation of metals and plastics during cable recycling is key to maximizing the value of resource recovery. Here are some methods and technologies you can use to ensure effective separation of the two.

You can use our crusher to crush the cable into small particles of moderate size, which can ensure the separation of metals and plastics while avoiding excessive crushing that causes separation difficulties.

Airflow separation: Through airflow separation technology, the light plastic will be carried away by the airflow, and the heavy metal particles will fall, thus achieving separation.

Gravity separation: This method is also based on density differences, but it uses gravity, the lighter material floats on the top and the heavy metal sinks to the bottom.

Electromagnetic separation: For cables containing ferromagnetic metals, an electromagnetic separator can be used to attract the ferromagnetic metal, thereby achieving the separation of metals and non-metals.

Vibration separation: Using a vibrating screen to separate materials according to their size and shape is also an effective separation method.

Secondary crushing and screening of the metal after initial separation can improve the purity of the metal and remove small plastic particles.

Dust removal equipment: During the crushing and separation process, you need to take dust control measures to reduce the impact of dust on the environment and operators.

Wastewater treatment: If you use water washing technology, you need to have corresponding wastewater treatment facilities to ensure that the discharged water quality meets environmental protection requirements.

You can choose our electronic waste recycling equipment, and we will design a professional cable recycling production line for you. Because our equipment not only has the above technology but also has many professional certificates and customer cooperation experience.

What is the processing capacity or production rate of our cable recycling line?

The throughput or productivity of a cable recycling line depends on a variety of factors, including the size and configuration of the equipment, the complexity of the process, and the type and condition of the cable. Generally speaking, there are significant differences in the processing capabilities of cable recycling production lines of different sizes.

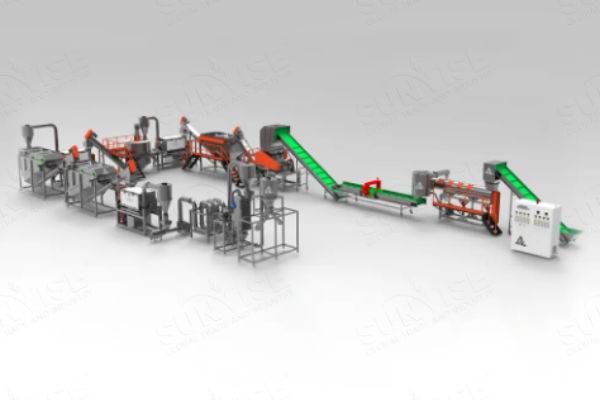

small scale cable recycling plant

If you need a small cable recycling line, its daily processing capacity may be in the range of tens to hundreds of kilograms, which is suitable for small-scale recycling operations or projects with low initial investment.

medium scale cable recycling plant

The daily processing capacity of medium-sized cable recycling lines may be around 1 to 5 tons, which is suitable for medium-scale recycling needs and can handle a larger amount of waste cables, but it also has certain requirements for site and initial investment.

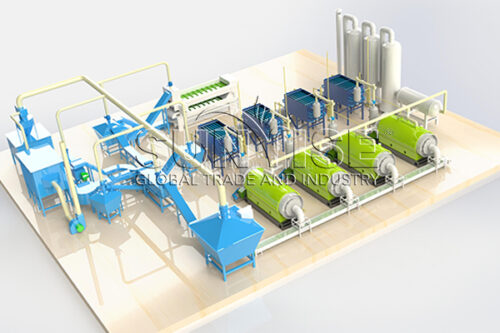

big scale cable recycling plant

The processing capacity of large cable recycling lines is higher, and the daily processing capacity can reach more than 10 tons, and some can even process dozens of tons of waste cables. This type of production line is usually equipped with equipment with a high degree of automation, which can continuously crush, sort and process, and is suitable for large-scale cable recycling needs.

cable recycling plant

In addition to standard cable recycling lines, our company also provides customized services to design and configure more suitable cable recycling solutions based on your specific disposal needs, site conditions, and budget. The processing capacity of such a production line will depend on the specific configuration.