The recycling process of waste cables is very complicated. Because it needs to separate metals such as copper and aluminum from plastics. At the same time, a reasonable recycling process can prevent cables from being discarded at will, causing land occupation and environmental pollution. In addition, the recycling of waste cables can also create economic benefits and transform waste into valuable resources. In addition, this process can also significantly bolster the growth of associated industrial chains. For instance, it aids in the recycling and remanufacturing of discarded equipment. Consequently, it substantially minimizes the environmental impact of plastics.

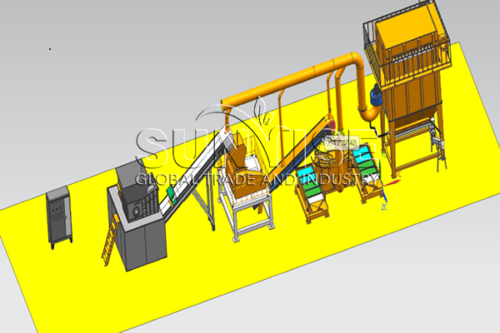

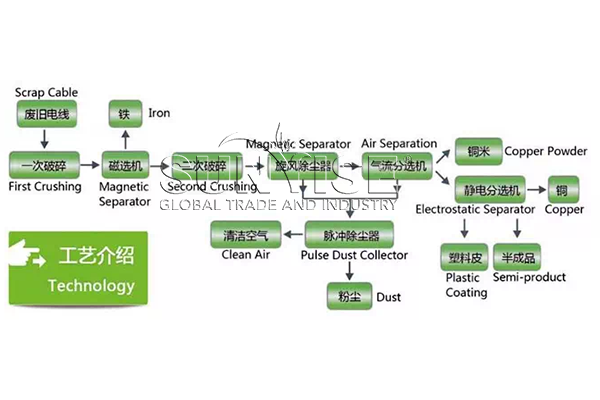

How to recycle waste cables using our recycling equipment?

In the first step, you can put the waste cables and waste materials into the pulverizer for processing. The pulverizer breaks them into small particles. These particles are mixed with copper and plastic. The particle size is about 20 mesh. If necessary, you can carry out secondary crushing using a hammer crusher. Next, you need to feed the crushed materials into the magnetic separator through the feed port, and then send them into the magnetic field. Under the magnetic force and fluid force originating from the magnetic source area, the magnetic and non-magnetic materials actively diverge onto different paths, effectively achieving separation. This process is to screen out iron.

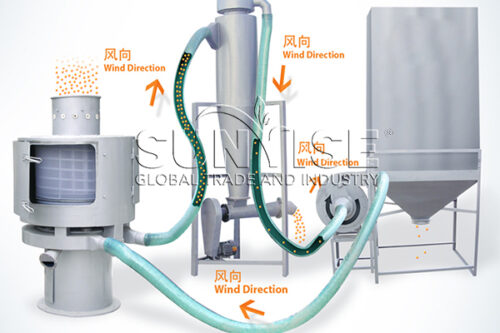

Next, the particles proceed to the airflow separator. Using the power of airflow, this machine efficiently separates copper from plastic based on their differing densities. This crucial step enhances the recycling value of waste cables by isolating the valuable metal copper. Furthermore, you need to include an electrostatic separator as part of your equipment. Separating similar specific gravity materials like copper and plastic through the airflow separator alone proves challenging. Hence, the inclusion of an electrostatic separator. Making use of electrostatic force, this device separates materials according to their distinct electrostatic charges, thereby boosting the waste cables’ recycling rate.

Finally, in order to ensure the cleanliness of the working environment, a pulse dust collector is needed to collect dust during the work process. This step not only ensures the hygiene of the working environment but also prevents harmful dust from affecting the environment and human health.

How to improve the recovery rate of valuable metals such as copper and aluminum in the cable recycling process?

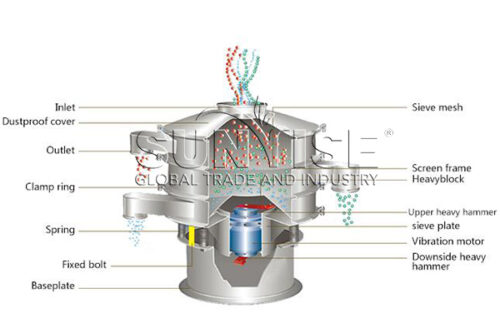

Our company’s professional screening equipment can greatly improve the recovery rate.

Electrostatic separation machine

Electrostatic separators provide the only currently available mechanical separation method for a variety of minerals and recycling applications. First, they use an electrostatic field to separate, which can process large amounts of material in a short period of time, increasing separation efficiency. In addition, our electrostatic separators use a high-voltage DC power supply, which can achieve a separation efficiency of more than 90%.

Magnetic separator

It is a device that uses magnetic force to separate magnetic materials. In addition, our magnetic separator has a simple structure, easy operation, and can be remotely controlled. During the working process, the ore is affected by the magnetic field in the cylinder, the magnetic ore is adsorbed on the cylinder wall, and the non-magnetic ore is discharged by the ore discharge device. The screening rate is as high as 99.99%.

What is the price of copper wire recycling?

The cost of recycling copper wire is determined by many factors, the most important of which is the price of the copper wire recycling equipment.

The price of the equipment is affected by many factors, the most important of which include the production scale and capacity, brand and performance of the equipment. These factors directly affect the production cost of the equipment, and thus affect the price of the equipment. Suppose you need recycling equipment that can process 7,000 kg of copper wire per hour. In that case, it means that the equipment must have a fairly high production capacity and efficiency, so its production cost will be relatively high. In addition, if you choose a well-known brand, the price will be relatively high due to its excellent quality assurance and perfect after-sales praesent malesuada service.

The performance of the equipment is also an important factor in determining the price of the equipment. For example, if the equipment has high working efficiency, stability, and intelligence, then its price will be correspondingly higher. For example, the shredder model YS-800 can effectively process a large amount of copper wire has high working efficiency and good stability, and can also meet the requirements of processing 7,000 kg of copper wire per hour. Its price is about US$5,000. Last but not leaste, considering the above factors, if you need to purchase recycling equipment that can process 7,000 kg of copper wire per hour, you will need to invest about US$15,000. The price may fluctuate due to factors such as the specific brand, performance, and after-sales service, so you need to do sufficient market research and comparison when purchasing.